Expansion of Industrial Automation

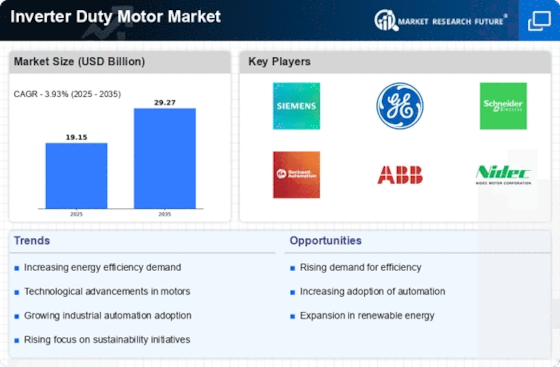

The Inverter Duty Motor Market is benefiting from the rapid expansion of industrial automation across various sectors. As industries increasingly adopt automated processes to enhance productivity and reduce labor costs, the demand for reliable and efficient motors is on the rise. Inverter duty motors are particularly well-suited for automated applications due to their ability to provide precise speed and torque control. According to industry reports, the industrial automation market is projected to grow at a compound annual growth rate (CAGR) of over 9% in the coming years. This growth is likely to drive the demand for inverter duty motors, as they are integral to the operation of automated machinery and equipment. Furthermore, the integration of advanced control systems in automation processes necessitates the use of high-performance motors, further solidifying the position of inverter duty motors in the market.

Increasing Demand from HVAC Systems

The Inverter Duty Motor Market is experiencing heightened demand from the heating, ventilation, and air conditioning (HVAC) sector. As energy efficiency becomes a critical consideration in building design and operation, inverter duty motors are increasingly favored for their ability to provide variable speed control and energy savings. HVAC systems equipped with inverter duty motors can adjust their output based on real-time demand, leading to significant reductions in energy consumption. Reports indicate that the HVAC market is expected to grow at a CAGR of approximately 6% over the next few years, driven by the need for energy-efficient solutions. This growth is likely to translate into increased sales of inverter duty motors, as they are integral to modern HVAC systems. Furthermore, the rising trend of smart buildings and automation in HVAC applications further supports the demand for these motors, positioning them as a key player in the market.

Growth in Renewable Energy Applications

The Inverter Duty Motor Market is poised for growth due to the increasing integration of renewable energy sources into the power grid. As the world shifts towards sustainable energy solutions, inverter duty motors are becoming essential components in renewable energy applications, such as wind and solar power systems. These motors are utilized in various capacities, including inverters and pumps, to optimize energy conversion and distribution. The Inverter Duty Motor Market is expected to witness substantial growth, with investments projected to reach trillions of dollars over the next decade. This trend is likely to create significant opportunities for inverter duty motor manufacturers, as the demand for efficient and reliable motors in renewable energy systems continues to rise. Additionally, the push for energy independence and reduced reliance on fossil fuels further enhances the relevance of inverter duty motors in this evolving landscape.

Rising Focus on Energy Efficiency Regulations

The Inverter Duty Motor Market is significantly influenced by the increasing focus on energy efficiency regulations imposed by governments and regulatory bodies. Many countries are implementing stringent energy efficiency standards for industrial equipment, including motors. For example, the International Electrotechnical Commission (IEC) has established standards that mandate higher efficiency levels for electric motors. This regulatory environment is compelling manufacturers to innovate and produce inverter duty motors that meet or exceed these standards. As a result, the market is witnessing a shift towards more energy-efficient solutions, which not only comply with regulations but also offer cost savings to end-users. The growing awareness of environmental sustainability further propels this trend, as industries seek to reduce their carbon footprint. Consequently, the demand for inverter duty motors is expected to rise, driven by compliance with energy efficiency regulations.

Technological Innovations in Inverter Duty Motors

The Inverter Duty Motor Market is experiencing a surge in technological innovations that enhance motor performance and efficiency. Advanced control algorithms and improved materials are being integrated into motor designs, leading to higher efficiency ratings and reduced energy consumption. For instance, the introduction of permanent magnet synchronous motors (PMSMs) has shown to increase efficiency by up to 10% compared to traditional induction motors. This trend is likely to drive the adoption of inverter duty motors across various sectors, including manufacturing and HVAC systems, where energy savings are paramount. Furthermore, the integration of smart technologies, such as IoT capabilities, allows for real-time monitoring and predictive maintenance, which can significantly reduce operational costs. As these technologies continue to evolve, they are expected to play a crucial role in shaping the future of the Inverter Duty Motor Market.