Growth in Automotive Sector

The automotive industry is increasingly adopting composite materials to improve fuel efficiency and reduce emissions, thereby driving the Invar Tooling In Composite Market. As electric vehicles gain traction, the need for lightweight components has become paramount. Invar tooling offers the necessary precision and stability for producing complex automotive parts. Market analysis suggests that the automotive composites market could reach approximately 25 billion dollars by 2025, with a significant portion attributed to Invar tooling applications. This growth is likely to create new opportunities for manufacturers specializing in Invar tooling, as they cater to the evolving needs of the automotive sector.

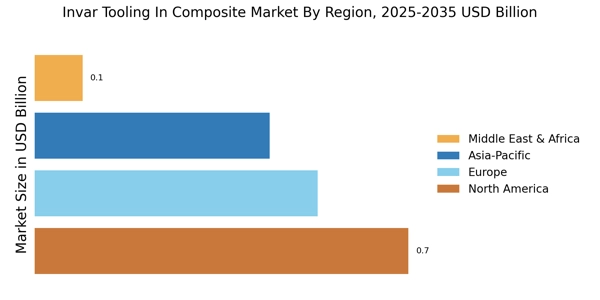

Emerging Markets and Economic Growth

Emerging markets are playing a pivotal role in the expansion of the Invar Tooling In Composite Market. As economies develop, there is a growing demand for advanced manufacturing capabilities, particularly in regions such as Asia-Pacific and Latin America. These markets are increasingly investing in infrastructure and technology, which is likely to drive the adoption of Invar tooling in various industries. The economic growth in these regions may lead to a compound annual growth rate of around 6% for the Invar tooling market, as manufacturers seek to enhance their production capabilities and meet the rising demand for composite materials.

Rising Demand in Aerospace Applications

The aerospace sector is a significant driver for the Invar Tooling In Composite Market, as the demand for lightweight and durable materials continues to rise. Invar tooling is particularly valued for its thermal stability and low thermal expansion, making it ideal for aerospace components that require high precision. Recent data indicates that the aerospace industry is expected to invest heavily in composite materials, with projections suggesting a market size of over 30 billion dollars by 2026. This trend is likely to bolster the demand for Invar tooling, as manufacturers seek reliable solutions to meet stringent aerospace standards and enhance performance.

Technological Innovations in Invar Tooling

The Invar Tooling In Composite Market is experiencing a surge in technological innovations that enhance manufacturing processes. Advanced techniques such as additive manufacturing and precision machining are being integrated into tooling production, allowing for more complex geometries and improved accuracy. These innovations not only reduce lead times but also lower production costs, making Invar tooling more accessible to various sectors. The market is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years, driven by these advancements. As manufacturers adopt these technologies, the efficiency and effectiveness of Invar tooling are likely to improve, further solidifying its position in composite applications.

Focus on Sustainable Manufacturing Practices

Sustainability is becoming a critical focus within the Invar Tooling In Composite Market, as manufacturers seek to minimize their environmental impact. The shift towards eco-friendly practices is prompting companies to adopt more sustainable materials and processes. Invar tooling, known for its durability and recyclability, aligns well with these sustainability goals. As regulations tighten and consumer preferences shift towards greener products, the demand for sustainable tooling solutions is expected to rise. This trend may lead to increased investments in research and development, fostering innovations that enhance the sustainability of Invar tooling in composite applications.