Infrastructure Development Projects

Infrastructure development projects are significantly influencing the Industrial Sheaves and Pulley Market. Governments and private entities are investing heavily in infrastructure, including transportation, energy, and construction sectors. This investment is expected to reach trillions of dollars over the next decade, creating a substantial demand for industrial sheaves and pulleys. These components are essential in cranes, conveyors, and other machinery used in construction and infrastructure projects. As such, the Industrial Sheaves and Pulley Market stands to benefit from this influx of projects, as the need for reliable and efficient lifting and moving solutions becomes increasingly critical. The ongoing urbanization trends further amplify this demand, suggesting a sustained growth trajectory for the market.

Increased Focus on Energy Efficiency

The Industrial Sheaves and Pulley Market is witnessing a shift towards energy efficiency, driven by both regulatory pressures and corporate sustainability goals. Companies are increasingly adopting energy-efficient solutions to reduce operational costs and minimize their environmental footprint. This trend is particularly evident in sectors such as manufacturing and logistics, where energy consumption is substantial. The market for energy-efficient industrial sheaves and pulleys is projected to grow, as these components can significantly enhance the performance of machinery by reducing energy losses. Furthermore, the implementation of stringent energy regulations is likely to compel manufacturers to innovate and develop more efficient products, thereby fostering growth within the Industrial Sheaves and Pulley Market.

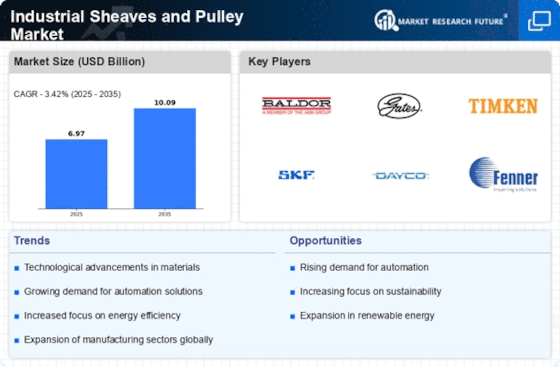

Rising Demand in Manufacturing Sector

The Industrial Sheaves and Pulley Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries increasingly focus on enhancing operational efficiency, the need for reliable and durable sheaves and pulleys becomes paramount. In recent years, the manufacturing sector has shown a compound annual growth rate (CAGR) of approximately 4.5%, indicating a robust growth trajectory. This growth is likely to propel the demand for industrial sheaves and pulleys, as they are integral components in various machinery and equipment. Furthermore, the ongoing trend towards mechanization in manufacturing processes suggests that the Industrial Sheaves and Pulley Market will continue to thrive, as companies seek to optimize their production capabilities and reduce downtime.

Growing Adoption of Automation Technologies

The growing adoption of automation technologies is a key driver for the Industrial Sheaves and Pulley Market. As industries strive for increased productivity and reduced labor costs, the integration of automated systems is becoming commonplace. Industrial sheaves and pulleys play a crucial role in these automated systems, facilitating the movement and control of materials and products. The automation market is projected to grow at a CAGR of around 9% over the next few years, which is likely to translate into heightened demand for industrial sheaves and pulleys. This trend suggests that the Industrial Sheaves and Pulley Market will continue to expand, as manufacturers seek to enhance their operational efficiency and competitiveness through automation.

Technological Innovations in Product Design

Technological innovations are reshaping the Industrial Sheaves and Pulley Market, as manufacturers increasingly leverage advanced materials and design techniques. The introduction of lightweight and high-strength materials, such as composites and alloys, is enhancing the performance and durability of sheaves and pulleys. Additionally, the integration of computer-aided design (CAD) and simulation technologies allows for more precise engineering and customization of products. This trend is expected to drive market growth, as companies seek to improve the efficiency and reliability of their machinery. The ongoing research and development efforts in the Industrial Sheaves and Pulley Market indicate a promising future, with potential advancements that could redefine industry standards and performance metrics.