Expansion of E-commerce

The rapid expansion of e-commerce is reshaping the Industrial Electronics Packaging Market. As online shopping continues to grow, the demand for efficient and protective packaging solutions has surged. E-commerce companies require packaging that not only safeguards products during transit but also enhances the unboxing experience for consumers. This has led to an increase in the development of customized packaging solutions that cater to specific product needs. Furthermore, the rise of direct-to-consumer models has prompted manufacturers to rethink their packaging strategies, focusing on both functionality and aesthetics. Market data suggests that the e-commerce packaging segment is expected to grow significantly, potentially reaching a valuation of several billion dollars in the next few years.

Technological Advancements

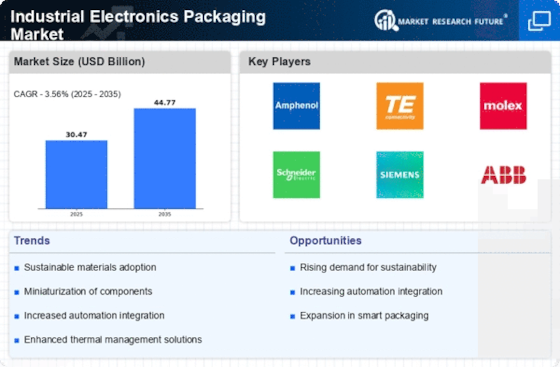

The Industrial Electronics Packaging Market is experiencing a surge in technological advancements that enhance product performance and reliability. Innovations in materials, such as advanced polymers and composites, are being integrated into packaging solutions, providing better protection against environmental factors. The adoption of smart technologies, including sensors and IoT capabilities, is also on the rise, allowing for real-time monitoring of packaged electronics. This trend is expected to drive market growth, as companies seek to improve the durability and functionality of their products. According to recent data, the market for smart packaging solutions is projected to grow at a compound annual growth rate of over 10% in the coming years, indicating a robust demand for advanced packaging technologies.

Increased Focus on Sustainability

Sustainability has emerged as a critical driver in the Industrial Electronics Packaging Market. With growing environmental concerns, manufacturers are increasingly adopting eco-friendly materials and practices in their packaging solutions. This shift is not merely a trend but a response to regulatory pressures and consumer preferences for sustainable products. The use of biodegradable and recyclable materials is becoming more prevalent, as companies aim to reduce their carbon footprint. Recent studies indicate that the market for sustainable packaging is expected to witness a significant increase, with projections suggesting a growth rate of around 8% annually. This focus on sustainability is likely to reshape the packaging landscape, encouraging innovation and responsible sourcing.

Rising Demand for Miniaturization

The trend towards miniaturization in electronics is significantly influencing the Industrial Electronics Packaging Market. As devices become smaller and more compact, the need for efficient and effective packaging solutions has intensified. This demand is driven by various sectors, including consumer electronics, automotive, and telecommunications, where space constraints are paramount. Packaging solutions must now accommodate intricate designs while ensuring protection and functionality. The market is responding to this challenge by developing innovative packaging that not only saves space but also enhances thermal management and electromagnetic shielding. This shift is likely to propel the market forward, as manufacturers prioritize compactness without compromising on quality.

Regulatory Compliance and Standards

Regulatory compliance is a pivotal factor influencing the Industrial Electronics Packaging Market. As governments and organizations implement stricter regulations regarding packaging materials and safety standards, manufacturers are compelled to adapt their practices accordingly. Compliance with these regulations not only ensures product safety but also enhances brand reputation and consumer trust. The need for packaging that meets international standards is becoming increasingly important, particularly in sectors such as automotive and aerospace, where safety is paramount. This focus on compliance is likely to drive innovation in packaging materials and designs, as companies strive to meet evolving regulatory requirements while maintaining product integrity.