Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are increasingly shaping the Industrial Dryer Market, as manufacturers must adhere to stringent guidelines. Industries such as pharmaceuticals and food processing are particularly affected, requiring dryers that meet specific safety and quality standards. Compliance with these regulations often necessitates the adoption of advanced drying technologies that ensure product integrity and safety. Recent data indicates that the pressure to meet these standards is likely to drive market growth by around 3% in the next few years. This focus on compliance not only protects consumers but also enhances the credibility of manufacturers, thereby fostering trust and loyalty in the marketplace.

Rising Energy Costs and Efficiency Demands

Rising energy costs are a critical driver in the Industrial Dryer Market, compelling manufacturers to seek more energy-efficient drying solutions. As energy prices fluctuate, the need for dryers that minimize energy consumption becomes paramount. Technologies such as regenerative thermal oxidizers and heat recovery systems are being adopted to enhance energy efficiency. Market analysis suggests that the demand for energy-efficient dryers could lead to a market growth of approximately 5% annually. This trend not only helps companies reduce operational costs but also aligns with broader sustainability goals, making energy-efficient dryers a strategic investment for manufacturers aiming to remain competitive in a cost-sensitive environment.

Sector-Specific Demand for Industrial Dryers

The Industrial Dryer Market is witnessing a surge in sector-specific demand, particularly from industries such as food processing, pharmaceuticals, and textiles. Each sector has unique drying requirements, driving the need for specialized drying equipment. For instance, the food processing industry requires dryers that maintain product quality while ensuring safety standards. Recent statistics reveal that the food processing sector alone accounts for nearly 30% of the total market share, highlighting its significance. As these industries continue to expand, the demand for tailored drying solutions is expected to grow, potentially increasing the market size by 4% in the coming years. This trend underscores the importance of innovation in developing dryers that cater to diverse industrial needs.

Technological Advancements in Drying Processes

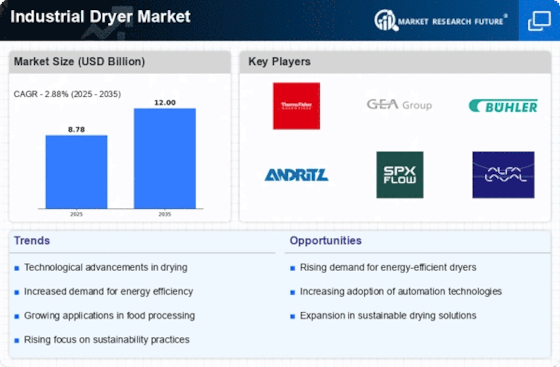

The Industrial Dryer Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as advanced heat pump technology and microwave drying are enhancing efficiency and reducing energy consumption. For instance, the integration of automation and IoT in drying systems allows for real-time monitoring and control, leading to optimized performance. According to recent data, the adoption of these technologies is projected to increase the market size significantly, with estimates suggesting a growth rate of approximately 5% annually. This trend indicates a shift towards more energy-efficient and cost-effective drying solutions, which are becoming essential for manufacturers aiming to improve productivity and reduce operational costs.

Sustainability Initiatives Driving Market Growth

Sustainability initiatives are increasingly influencing the Industrial Dryer Market, as companies strive to minimize their environmental impact. The demand for eco-friendly drying solutions is on the rise, with manufacturers seeking technologies that reduce emissions and energy usage. For example, the implementation of solar-assisted drying systems is gaining traction, as they utilize renewable energy sources to power drying processes. Market data indicates that the shift towards sustainable practices could lead to a market expansion of around 6% over the next few years. This focus on sustainability not only aligns with regulatory requirements but also appeals to environmentally conscious consumers, thereby enhancing brand reputation and market competitiveness.