Growth in E-commerce and Packaging

The Industrial Dispensing System Equipment Market is significantly influenced by the rapid growth of e-commerce and the corresponding demand for efficient packaging solutions. As online shopping continues to expand, companies are seeking innovative dispensing systems to streamline their packaging processes. This shift is particularly evident in the food and beverage sector, where the need for quick and accurate dispensing of products is paramount. Market analysis indicates that the packaging industry is expected to grow by approximately 4.8% annually, which directly correlates with the increasing adoption of advanced dispensing technologies. Consequently, the Industrial Dispensing System Equipment Market is poised to benefit from this trend, as businesses invest in equipment that enhances productivity and meets consumer expectations.

Expansion of Manufacturing Facilities

The Industrial Dispensing System Equipment Market is benefiting from the expansion of manufacturing facilities across various sectors. As companies seek to increase production capacity and meet rising consumer demand, there is a corresponding need for advanced dispensing systems that can efficiently handle larger volumes. This trend is particularly evident in the automotive and electronics industries, where manufacturers are investing in state-of-the-art equipment to enhance their production lines. Recent reports indicate that manufacturing output is projected to grow by 3.5% annually, which is likely to drive further investments in dispensing technologies. Consequently, the Industrial Dispensing System Equipment Market is expected to thrive as manufacturers prioritize the integration of efficient dispensing systems into their operations.

Increased Focus on Safety and Compliance

The Industrial Dispensing System Equipment Market is witnessing an increased focus on safety and compliance regulations across various sectors. As industries face stricter guidelines regarding the handling and dispensing of hazardous materials, the demand for compliant dispensing systems is on the rise. Companies are investing in equipment that not only meets regulatory standards but also enhances workplace safety. This trend is particularly prominent in the chemical and pharmaceutical industries, where the consequences of non-compliance can be severe. Market data suggests that the safety equipment market is expected to grow by 5.2% annually, indicating a strong correlation with the demand for compliant dispensing systems. Thus, the Industrial Dispensing System Equipment Market is likely to see continued growth as businesses prioritize safety and regulatory adherence.

Rising Demand for Precision Manufacturing

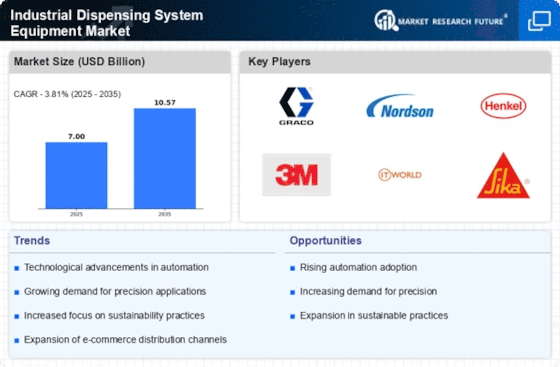

The Industrial Dispensing System Equipment Market is experiencing a notable surge in demand for precision manufacturing processes. Industries such as automotive, electronics, and pharmaceuticals are increasingly adopting advanced dispensing systems to ensure accuracy and consistency in production. This trend is driven by the need for high-quality products that meet stringent regulatory standards. According to recent data, the precision manufacturing sector is projected to grow at a compound annual growth rate of 6.5% over the next five years, further fueling the need for sophisticated dispensing solutions. As manufacturers strive to enhance operational efficiency and reduce waste, the adoption of precision dispensing systems becomes imperative, thereby propelling the Industrial Dispensing System Equipment Market forward.

Technological Advancements in Dispensing Systems

Technological advancements are playing a crucial role in shaping the Industrial Dispensing System Equipment Market. Innovations such as automated dispensing systems, real-time monitoring, and IoT integration are enhancing the efficiency and reliability of dispensing processes. These technologies enable manufacturers to optimize their operations, reduce downtime, and improve product quality. For instance, the integration of smart sensors allows for precise control over dispensing volumes, which is essential in industries like pharmaceuticals and chemicals. As these technologies continue to evolve, they are expected to drive a substantial increase in the adoption of advanced dispensing systems, thereby positively impacting the Industrial Dispensing System Equipment Market.