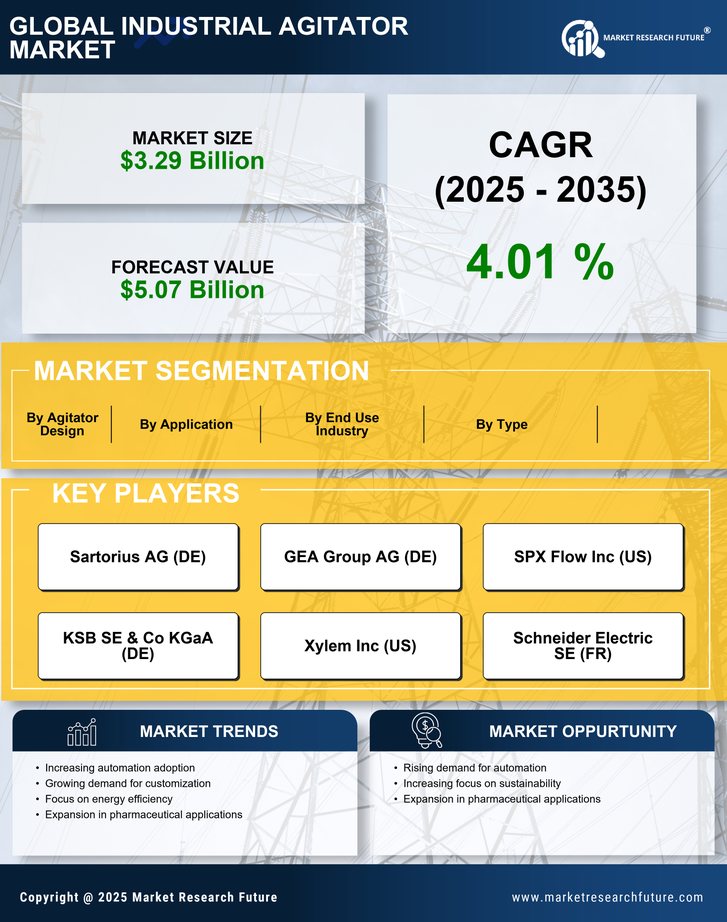

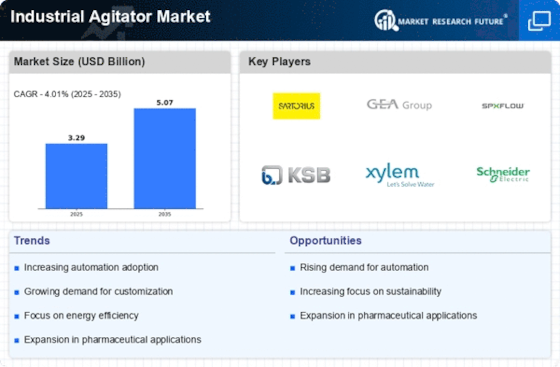

Pharmaceutical Industry Expansion

The expansion of the pharmaceutical industry is a critical factor influencing the Industrial Agitator Market. As the demand for biopharmaceuticals and advanced drug formulations increases, the need for specialized mixing equipment becomes essential. The pharmaceutical sector is projected to grow at a rate of 6.5% in 2025, necessitating the use of high-performance agitators that can handle complex formulations. This growth is likely to drive investments in research and development, leading to the introduction of new agitator technologies tailored for the pharmaceutical applications, thereby enhancing the overall market landscape.

Growth in Food and Beverage Sector

The food and beverage sector is a significant driver for the Industrial Agitator Market, as it requires precise mixing and blending processes to ensure product quality and safety. With the increasing consumer preference for processed and packaged foods, the demand for industrial agitators is expected to rise. In 2025, the food and beverage industry is anticipated to contribute around 30% to the overall market share. This trend indicates a shift towards automation and efficiency in production lines, prompting manufacturers to innovate and adapt their agitator designs to cater to the specific needs of this sector.

Rising Demand in Chemical Processing

The Industrial Agitator Market is experiencing a notable increase in demand driven by the chemical processing sector. As industries seek to enhance production efficiency, the need for effective mixing solutions becomes paramount. In 2025, the chemical processing industry is projected to account for a substantial share of the market, with estimates suggesting a growth rate of approximately 5.2% annually. This growth is attributed to the rising production of specialty chemicals and the need for consistent product quality. Consequently, manufacturers are investing in advanced agitator technologies to meet these demands, thereby propelling the Industrial Agitator Market forward.

Environmental Regulations and Compliance

Increasing environmental regulations are shaping the Industrial Agitator Market, as companies strive to comply with stringent standards. The push for sustainable practices is compelling manufacturers to develop agitators that minimize energy consumption and reduce waste. In 2025, it is estimated that around 40% of companies will prioritize eco-friendly solutions in their operations. This trend not only aligns with regulatory requirements but also appeals to environmentally conscious consumers. As a result, the market is likely to witness a surge in demand for energy-efficient agitators, which could redefine operational practices across various industries.

Technological Innovations in Agitation Solutions

Technological innovations are a driving force in the Industrial Agitator Market, as advancements in materials and design enhance performance and efficiency. The integration of smart technologies, such as IoT and automation, is transforming traditional mixing processes. In 2025, it is projected that the adoption of smart agitators will increase by 25%, reflecting a shift towards more intelligent manufacturing solutions. These innovations not only improve operational efficiency but also provide real-time monitoring capabilities, allowing for better control over mixing processes. Consequently, the market is likely to evolve, with manufacturers focusing on developing cutting-edge agitation solutions to meet the demands of various industries.