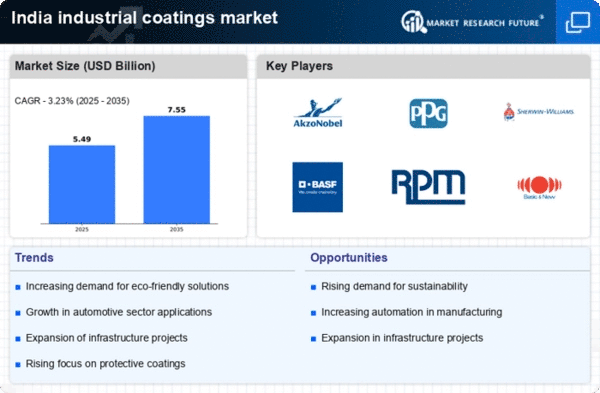

The industrial coatings market in India is characterized by a dynamic competitive landscape, driven by increasing demand across various sectors such as automotive, construction, and manufacturing. Key players are actively pursuing strategies that emphasize innovation, sustainability, and regional expansion. Companies like AkzoNobel (NL) and PPG Industries (US) are focusing on enhancing their product portfolios with eco-friendly solutions, while Sherwin-Williams (US) is leveraging digital transformation to optimize customer engagement and operational efficiency. These strategic initiatives collectively shape a competitive environment that is increasingly focused on meeting regulatory standards and consumer preferences for sustainable products.In terms of business tactics, localizing manufacturing and optimizing supply chains are critical for companies operating in this market. The competitive structure appears moderately fragmented, with several players vying for market share. However, the influence of major companies like BASF (DE) and Nippon Paint Holdings (JP) is substantial, as they continue to innovate and expand their presence. This competitive interplay fosters an environment where agility and responsiveness to market demands are paramount.

In October AkzoNobel (NL) announced the launch of a new line of water-based industrial coatings designed to reduce VOC emissions significantly. This strategic move not only aligns with global sustainability trends but also positions the company as a leader in environmentally friendly solutions. The introduction of these products is likely to enhance AkzoNobel's market share, particularly among environmentally conscious consumers and industries.

In September PPG Industries (US) expanded its manufacturing capabilities in India by investing $50 million in a new facility aimed at producing high-performance coatings. This investment underscores PPG's commitment to meeting the growing demand in the region while also enhancing its supply chain efficiency. The facility is expected to create approximately 200 jobs, further solidifying PPG's presence in the Indian market and contributing to local economic growth.

In August Sherwin-Williams (US) entered into a strategic partnership with a leading Indian construction firm to develop customized coatings solutions for the infrastructure sector. This collaboration is indicative of Sherwin-Williams' strategy to leverage local expertise and enhance its product offerings. By aligning with a prominent player in the construction industry, Sherwin-Williams is likely to gain valuable insights into market needs, thereby strengthening its competitive position.

As of November current trends in the industrial coatings market are increasingly defined by digitalization, sustainability, and the integration of AI technologies. Strategic alliances are becoming more prevalent, as companies recognize the value of collaboration in driving innovation and efficiency. Looking ahead, competitive differentiation is expected to evolve, with a notable shift from price-based competition to a focus on technological advancements, sustainable practices, and reliable supply chains. This transition may redefine market dynamics, compelling companies to innovate continuously to maintain their competitive edge.