Growing Automotive Sector Innovations

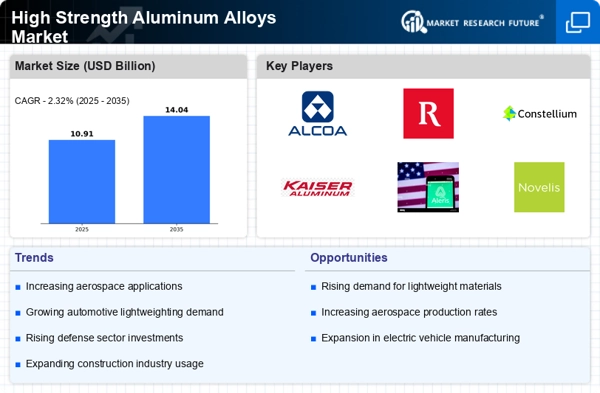

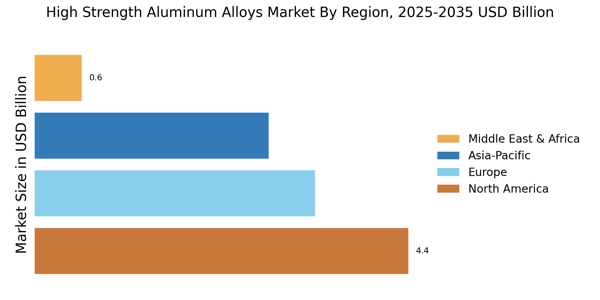

The automotive sector is undergoing a transformation, with a strong emphasis on lightweight materials to improve fuel efficiency and reduce emissions. High strength aluminum alloys are increasingly being adopted in vehicle manufacturing, particularly in structural components and body panels. The High Strength Aluminum Alloys Market is poised to benefit from this trend, as automakers strive to meet stringent regulatory standards and consumer demands for more sustainable vehicles. Recent data suggests that the automotive industry is expected to grow at a compound annual growth rate of approximately 3% over the next few years, further driving the adoption of high strength aluminum alloys. This shift towards lightweight materials is likely to enhance vehicle performance while contributing to overall sustainability goals.

Rising Aerospace Industry Requirements

The aerospace industry is a significant driver for the High Strength Aluminum Alloys Market, as it demands materials that offer exceptional strength and lightweight characteristics. With the increasing focus on fuel efficiency and performance, aerospace manufacturers are increasingly turning to high strength aluminum alloys for aircraft components. Recent statistics indicate that the aerospace sector is projected to grow at a rate of around 4% annually, which is likely to bolster the demand for these alloys. The ability of high strength aluminum alloys to withstand extreme conditions while minimizing weight makes them ideal for applications in both commercial and military aircraft. This trend is expected to continue, as the aerospace industry seeks to innovate and enhance the performance of its fleet.

Increasing Demand in Construction Sector

The construction sector is experiencing a notable surge in demand for high strength aluminum alloys, primarily due to their lightweight and durable properties. These alloys are increasingly utilized in structural applications, such as bridges and high-rise buildings, where strength-to-weight ratio is critical. The High Strength Aluminum Alloys Market is projected to benefit from this trend, as construction activities expand in various regions. According to recent data, the construction industry is expected to grow at a compound annual growth rate of approximately 5% over the next few years, further driving the demand for high strength aluminum alloys. This growth is likely to be fueled by urbanization and infrastructure development initiatives, which emphasize the need for materials that can withstand environmental stresses while maintaining structural integrity.

Emerging Applications in Renewable Energy

The renewable energy sector is emerging as a new frontier for the High Strength Aluminum Alloys Market. As the world shifts towards sustainable energy solutions, high strength aluminum alloys are being utilized in the construction of wind turbines and solar panel frames. These materials offer the necessary strength and corrosion resistance required for outdoor applications, making them ideal for renewable energy infrastructure. The increasing investments in renewable energy projects are likely to drive the demand for high strength aluminum alloys, as manufacturers seek materials that can withstand harsh environmental conditions. Recent projections indicate that the renewable energy market is expected to grow significantly, potentially increasing the demand for high strength aluminum alloys in the coming years.

Advancements in Manufacturing Technologies

Technological advancements in manufacturing processes are playing a pivotal role in shaping the High Strength Aluminum Alloys Market. Innovations such as additive manufacturing and advanced casting techniques are enabling the production of high-performance alloys with enhanced properties. These advancements not only improve the mechanical characteristics of the alloys but also reduce production costs and time. For instance, the introduction of 3D printing in alloy production has shown potential to decrease waste and increase design flexibility. As manufacturers adopt these cutting-edge technologies, the market is likely to witness a shift towards more efficient and sustainable production methods, thereby attracting new applications across various industries, including aerospace and automotive.