North America : Market Leader in Services

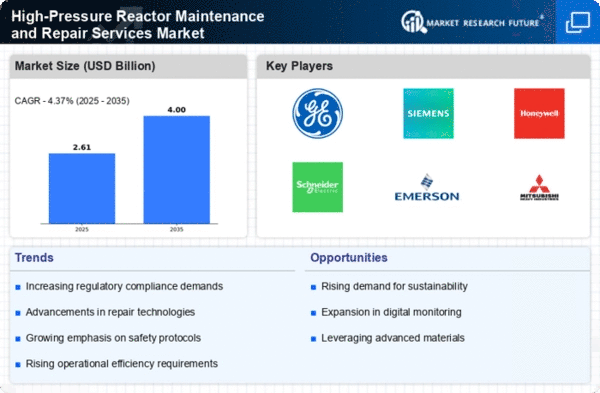

North America leads the High-Pressure Reactor Maintenance and Repair Services Market, holding a significant share of 1.25 billion. The region's growth is driven by stringent safety regulations, increasing demand for energy efficiency, and technological advancements in reactor design. The presence of major players like General Electric and Honeywell further fuels market expansion, supported by government initiatives promoting infrastructure upgrades and maintenance standards.

The United States is the primary contributor, with a robust industrial base and a focus on nuclear and chemical sectors. Competitive dynamics are shaped by key players such as Siemens and Emerson Electric, who are investing in innovative solutions to enhance service efficiency. The market is characterized by strategic partnerships and collaborations aimed at improving service delivery and customer satisfaction, ensuring a strong foothold in the global landscape.

Europe : Emerging Market Dynamics

Europe's High-Pressure Reactor Maintenance and Repair Services Market is valued at 0.75 billion, driven by increasing regulatory requirements and a shift towards sustainable energy solutions. The region is witnessing a rise in demand for maintenance services due to aging infrastructure and the need for compliance with EU regulations. Countries like Germany and France are at the forefront, investing in modernization and safety enhancements to meet stringent standards.

Germany, with its strong industrial sector, is a key player, supported by companies like Siemens and Schneider Electric. The competitive landscape is marked by innovation and collaboration among service providers to enhance operational efficiency. The European market is also influenced by EU directives aimed at improving safety and environmental standards, fostering a conducive environment for growth in maintenance services.

Asia-Pacific : Rapid Growth Potential

The Asia-Pacific region, valued at 0.4 billion, is rapidly emerging in the High-Pressure Reactor Maintenance and Repair Services Market. The growth is fueled by increasing industrialization, energy demands, and investments in nuclear energy. Countries like Japan and China are leading the charge, focusing on enhancing reactor safety and efficiency through advanced maintenance practices and regulatory compliance.

Japan's commitment to nuclear safety post-Fukushima has led to significant investments in maintenance services, with key players like Mitsubishi Heavy Industries playing a crucial role. The competitive landscape is evolving, with local and international firms vying for market share. As the region continues to expand its energy portfolio, the demand for high-quality maintenance services is expected to rise, positioning Asia-Pacific as a vital player in the global market.

Middle East and Africa : Emerging Market Opportunities

The Middle East and Africa region, with a market size of 0.1 billion, is gradually developing in the High-Pressure Reactor Maintenance and Repair Services Market. The growth is driven by increasing investments in energy infrastructure and a focus on safety regulations. Countries like the UAE and South Africa are beginning to recognize the importance of maintenance services in ensuring operational efficiency and safety in their energy sectors.

The competitive landscape is still in its nascent stages, with a few key players starting to establish their presence. Local firms are beginning to collaborate with international companies to enhance service offerings and meet the growing demand for maintenance solutions. As the region continues to invest in energy projects, the need for specialized maintenance services is expected to grow, presenting significant opportunities for market players.