Growth in Aerospace Applications

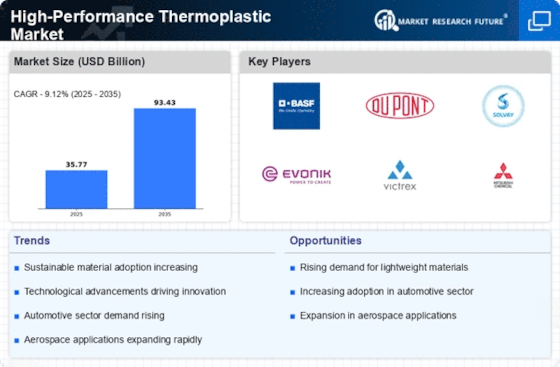

The aerospace industry is witnessing a surge in the utilization of high-performance thermoplastics, primarily due to their lightweight nature and superior strength-to-weight ratios. These materials are essential for enhancing fuel efficiency and overall aircraft performance. In 2025, the high-performance thermoplastic market is expected to benefit from increased demand for advanced composites in aircraft manufacturing. The trend towards reducing aircraft weight while maintaining structural integrity aligns with the properties of high-performance thermoplastics. Furthermore, as airlines focus on sustainability and operational efficiency, the adoption of these materials is likely to expand, indicating a promising outlook for the high-performance thermoplastic market in aerospace applications.

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable shift towards lightweight materials, which enhances fuel efficiency and reduces emissions. High-performance thermoplastics are increasingly favored due to their excellent mechanical properties and resistance to heat and chemicals. In 2025, the automotive industry is projected to account for a substantial share of the high-performance thermoplastic market, driven by the need for innovative materials that meet stringent regulatory standards. As manufacturers seek to improve vehicle performance while adhering to environmental regulations, the adoption of these materials is likely to accelerate. This trend suggests a robust growth trajectory for the high-performance thermoplastic market, as automotive companies invest in research and development to integrate these advanced materials into their production processes.

Increasing Focus on Sustainable Materials

The emphasis on sustainability is reshaping the high-performance thermoplastic market, as industries seek eco-friendly alternatives to traditional materials. The demand for recyclable and biodegradable thermoplastics is on the rise, driven by consumer preferences and regulatory pressures. In 2025, the market is anticipated to expand as manufacturers develop sustainable high-performance thermoplastics that meet environmental standards without compromising performance. This shift towards sustainability not only aligns with global initiatives but also presents opportunities for innovation within the high-performance thermoplastic market. Companies that prioritize sustainable practices are likely to gain a competitive edge, further propelling market growth.

Technological Innovations in Material Science

Technological advancements in material science are playing a pivotal role in the evolution of the high-performance thermoplastic market. Innovations such as enhanced processing techniques and the development of new polymer blends are enabling manufacturers to produce materials with superior properties. In 2025, the market is expected to witness a rise in the introduction of novel thermoplastic formulations that offer improved thermal stability and mechanical performance. These advancements not only cater to the increasing demands of various industries but also enhance the versatility of high-performance thermoplastics. As companies invest in research and development, the high-performance thermoplastic market is likely to experience significant growth driven by these technological breakthroughs.

Expansion in Electronics and Electrical Applications

The electronics and electrical sectors are increasingly adopting high-performance thermoplastics due to their excellent electrical insulation properties and thermal stability. As the demand for lightweight and durable materials grows, the high-performance thermoplastic market is poised for expansion in these applications. In 2025, the market is expected to see a rise in the use of these materials in components such as connectors, housings, and circuit boards. The trend towards miniaturization and increased functionality in electronic devices further drives the need for advanced thermoplastics. This indicates a promising future for the high-performance thermoplastic market, as manufacturers seek to leverage these materials to enhance product performance and reliability.