Market Analysis

In-depth Analysis of High Performance Epoxy Market Industry Landscape

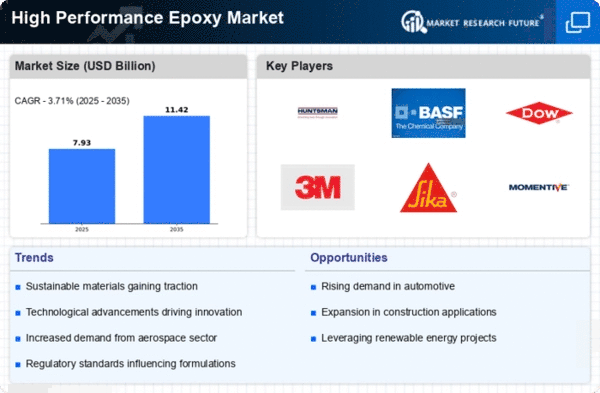

The global high-performance epoxy market is set to reach US$ 15.23 BN by 2030, growing at a 5.83% CAGR between years 2022-2030. The market’s dynamic framework is influenced by various factors that collectively shape its growth and development. The building and construction industry is the largest end-user of epoxy. They use these materials to glue structures, make floors and fix concrete problems. The need for strong epoxy in building is growing because it sticks well, lasts a long time and can stand up to tough weather. Super strong epoxy resins are widely used in airplane and army businesses for things like composite materials, glue and coverings. Epoxy is used a lot in making things like airplane parts and military stuff because it's strong but not too heavy. The electronics business often uses strong epoxy in encapsulation, potting and bonding of electronic parts. The small-size pattern in gadgets and the want to keep things safe from nature's factors cause a need for epoxy that can stand high heat or power levels. Continual improvements in special materials, especially for cars and planes, help increase the need for strong epoxy. These things are very important in making light and fuel-saving cars. They make these vehicles stronger from inside out. The renewable energy business, especially wind power, uses strong epoxy to make blades for wind turbines. Epoxy resins give the needed toughness, bendability and stickiness to handle hard conditions in wind energy projects. Considering the environment pushes market changes, which results in creating better and green epoxy mixtures. Businesses work to lessen harm caused by making and using epoxy. They use nature-made materials instead of old ones, and make stuff more friendly for the earth in how they do things step by step. Nanotech helps the strong glue market by making special nano-improved mixtures. Nanoepoxies help things be stronger, stick better and resist wear. They are used in many different areas to make new improvements. Many industries want high-performance epoxy coatings because they can resist rust and chemicals, as well as last a long time. The car, oil and gas, plus marine businesses really help a lot with the need for protective coatings in the market. Building and making cars affect how much people want the strong epoxy.

Leave a Comment