Rising Demand in Automotive Sector

The automotive sector is experiencing a notable surge in demand for high performance additives, driven by the need for enhanced fuel efficiency and reduced emissions. High performance additives play a crucial role in improving the performance of automotive fluids and materials, thereby contributing to the overall efficiency of vehicles. In 2025, the automotive industry is projected to account for a significant share of the high performance additive market, with an estimated growth rate of around 6.5% annually. This trend indicates a shift towards more sustainable practices within the automotive sector, as manufacturers increasingly seek to meet stringent regulatory standards. Consequently, the high performance additive market is likely to benefit from this growing demand, as companies invest in innovative solutions to enhance vehicle performance and sustainability.

Expansion in Aerospace Applications

The aerospace industry is witnessing an expansion in the utilization of high performance additives, primarily due to the increasing focus on lightweight materials and enhanced performance characteristics. High performance additives are essential in the formulation of advanced composites and coatings that are used in aircraft manufacturing. As of 2025, the aerospace sector is expected to contribute significantly to the high performance additive market, with a projected growth rate of approximately 7%. This growth is attributed to the rising demand for fuel-efficient aircraft and the need for materials that can withstand extreme conditions. The integration of high performance additives in aerospace applications not only improves the durability and performance of components but also aligns with the industry's commitment to sustainability and innovation.

Regulatory Compliance and Standards

The high performance additive market is significantly influenced by regulatory compliance and standards that govern various sectors, including automotive, aerospace, and construction. As regulations become increasingly stringent, manufacturers are compelled to adopt high performance additives that meet these requirements. In 2025, the market is expected to see a rise in demand for additives that comply with environmental and safety standards, with a projected growth rate of around 6%. This shift is likely to drive innovation within the high performance additive market, as companies invest in research and development to create compliant products. The emphasis on regulatory compliance not only enhances product safety and performance but also fosters consumer trust and market acceptance.

Increased Focus on Energy Efficiency

The high performance additive market is experiencing an increased focus on energy efficiency across various sectors, including construction, automotive, and industrial applications. As organizations strive to reduce their carbon footprint and operational costs, the demand for additives that enhance energy efficiency is on the rise. In 2025, it is anticipated that the market for energy-efficient high performance additives will grow by approximately 5.5% annually. This trend is indicative of a broader movement towards sustainability, as companies seek to implement solutions that not only improve performance but also contribute to environmental conservation. High performance additives are instrumental in achieving these goals, as they optimize the performance of materials and systems, thereby reducing energy consumption and waste.

Technological Innovations in Additive Manufacturing

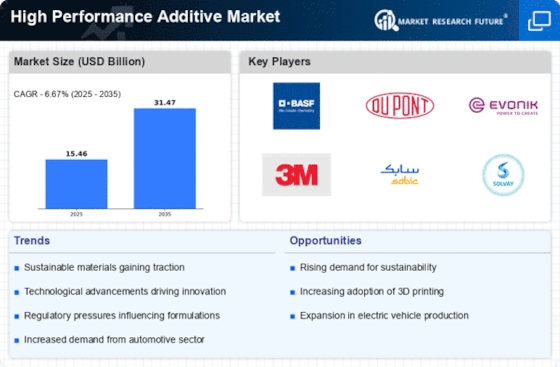

Technological innovations in additive manufacturing are reshaping the landscape of the high performance additive market. The advent of 3D printing technologies has enabled the production of complex geometries and customized components that were previously unattainable. As of October 2025, the market for high performance additives used in additive manufacturing is projected to grow at a compound annual growth rate of around 8%. This growth is driven by the increasing adoption of 3D printing across various industries, including aerospace, automotive, and healthcare. High performance additives enhance the mechanical properties and thermal stability of printed materials, thereby expanding their application potential. The ongoing advancements in additive manufacturing technologies suggest a promising future for the high performance additive market, as companies continue to explore innovative solutions to meet diverse manufacturing needs.