Growth in E-commerce and Logistics

The Heavy Duty Robotic Arm Market is significantly influenced by the growth of e-commerce and logistics sectors. With the rise in online shopping, warehouses and distribution centers are increasingly automating their operations to meet consumer demands for faster delivery. Heavy-duty robotic arms are being utilized for tasks such as sorting, packing, and palletizing, which enhances operational efficiency. Market data suggests that the logistics automation market is expected to reach USD 50 billion by 2027, indicating a robust opportunity for heavy-duty robotic arms. This trend underscores the necessity for automation in handling the increasing volume of goods.

Technological Advancements in Robotics

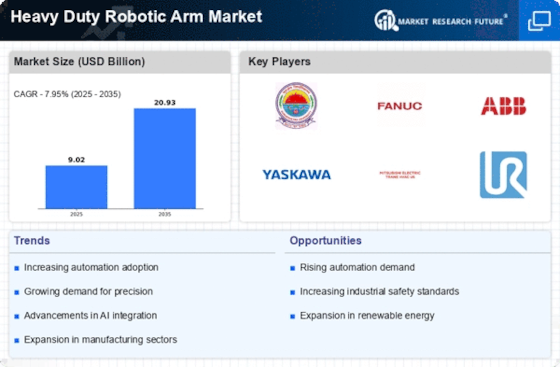

Technological advancements play a pivotal role in shaping the Heavy Duty Robotic Arm Market. Innovations in artificial intelligence, machine learning, and sensor technology are enhancing the capabilities of robotic arms, making them more efficient and versatile. For instance, the introduction of collaborative robots, or cobots, allows for safer interaction between humans and machines. This evolution is expected to drive market growth, with projections indicating a potential increase in market size by 15% by 2026. As industries adopt these advanced technologies, the demand for heavy-duty robotic arms is likely to escalate, reflecting a broader trend towards automation.

Rising Demand for Precision Manufacturing

The Heavy Duty Robotic Arm Market is experiencing a notable surge in demand for precision manufacturing. Industries such as automotive, aerospace, and electronics are increasingly relying on robotic arms to enhance accuracy and reduce human error in production processes. This trend is driven by the need for high-quality products and the minimization of waste. According to recent data, the precision manufacturing sector is projected to grow at a compound annual growth rate of approximately 7% over the next five years. As manufacturers seek to optimize their operations, the integration of heavy-duty robotic arms becomes essential, thereby propelling the market forward.

Focus on Sustainability and Energy Efficiency

The Heavy Duty Robotic Arm Market is increasingly aligned with sustainability and energy efficiency goals. As industries face pressure to reduce their carbon footprint, the adoption of energy-efficient robotic solutions is becoming paramount. Heavy-duty robotic arms are designed to optimize energy consumption while maintaining high performance levels. This focus on sustainability is not only beneficial for the environment but also aligns with corporate social responsibility initiatives. Market analysis indicates that companies investing in sustainable technologies are likely to see a return on investment through reduced operational costs and enhanced brand reputation. This trend is expected to further drive the demand for heavy-duty robotic arms.

Increased Investment in Industrial Automation

Investment in industrial automation is a key driver for the Heavy Duty Robotic Arm Market. Companies are allocating substantial resources to upgrade their manufacturing processes, aiming to improve productivity and reduce operational costs. This shift is particularly evident in sectors like manufacturing and construction, where heavy-duty robotic arms are being deployed to perform labor-intensive tasks. Recent statistics indicate that the industrial automation market is projected to grow by 10% annually, reflecting a strong commitment to integrating advanced robotics. As businesses recognize the long-term benefits of automation, the demand for heavy-duty robotic arms is expected to rise correspondingly.