Technological Innovations in Casting Processes

The Grid Casting Machine Market is significantly influenced by ongoing technological innovations in casting processes. Advancements in automation, artificial intelligence, and machine learning are transforming traditional casting methods, making them more efficient and precise. These innovations enable manufacturers to produce complex geometries and reduce cycle times, which are crucial for meeting the demands of modern industries. The integration of smart technologies into grid casting machines allows for real-time monitoring and adjustments, enhancing overall production quality. Market analysts suggest that the adoption of these advanced technologies could lead to a 15% reduction in production costs, making grid casting machines an attractive investment for manufacturers. As industries continue to evolve, the demand for technologically advanced casting solutions is expected to rise, further propelling the growth of the grid casting machine market.

Expansion of Automotive and Aerospace Industries

The Grid Casting Machine Market is benefiting from the expansion of the automotive and aerospace industries, which are increasingly relying on advanced manufacturing technologies. As these sectors grow, the demand for high-performance components produced through grid casting processes is expected to rise. The automotive industry, in particular, is undergoing a transformation with the shift towards electric vehicles, necessitating the production of lightweight and durable parts. Similarly, the aerospace sector requires precision-engineered components that grid casting machines can provide. Market forecasts suggest that the automotive and aerospace industries will experience a combined growth rate of 7% annually, further driving the demand for grid casting machines. This expansion presents a lucrative opportunity for manufacturers to capitalize on the increasing need for advanced casting solutions in these high-growth sectors.

Increased Investment in Infrastructure Development

The Grid Casting Machine Market is poised for growth due to increased investment in infrastructure development across various sectors. Governments and private entities are allocating substantial budgets for infrastructure projects, including transportation, energy, and construction. This trend is expected to drive the demand for grid casting machines, which are essential for producing high-quality components used in these projects. For instance, the construction of new highways and bridges necessitates the use of durable materials, which grid casting machines can efficiently produce. Recent reports indicate that infrastructure spending is anticipated to rise by 8% annually, further fueling the need for advanced manufacturing solutions. As a result, the grid casting machine market is likely to benefit from this influx of investment, positioning it as a critical player in the infrastructure sector.

Rising Demand for Efficient Manufacturing Processes

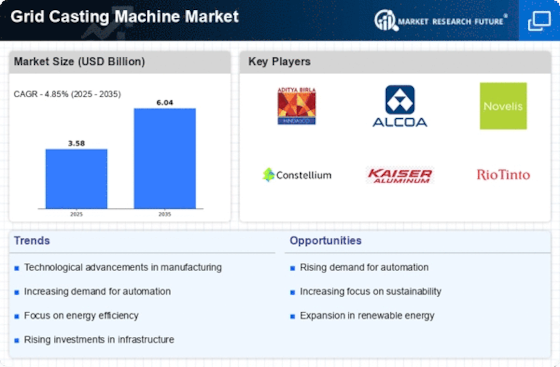

The Grid Casting Machine Market is experiencing a surge in demand driven by the need for more efficient manufacturing processes. Industries are increasingly seeking solutions that enhance productivity while minimizing waste. The adoption of grid casting machines, which streamline the production of metal components, is indicative of this trend. According to recent data, the market for grid casting machines is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This growth is largely attributed to the rising need for precision in manufacturing, which grid casting machines provide through their advanced technology. As manufacturers strive to meet stringent quality standards, the integration of these machines into production lines appears to be a strategic move to enhance operational efficiency.

Growing Focus on Sustainable Manufacturing Practices

The Grid Casting Machine Market is increasingly shaped by a growing focus on sustainable manufacturing practices. As environmental concerns gain prominence, manufacturers are seeking ways to reduce their carbon footprint and enhance resource efficiency. Grid casting machines, which optimize material usage and minimize waste, align well with these sustainability goals. Recent studies indicate that companies adopting sustainable practices can achieve up to a 20% reduction in operational costs. This trend is prompting manufacturers to invest in grid casting technology that not only meets production needs but also adheres to environmental regulations. The shift towards sustainability is likely to drive innovation within the grid casting machine market, as companies strive to develop eco-friendly solutions that cater to the evolving demands of consumers and regulatory bodies.