Rising Demand in Recycling Industry

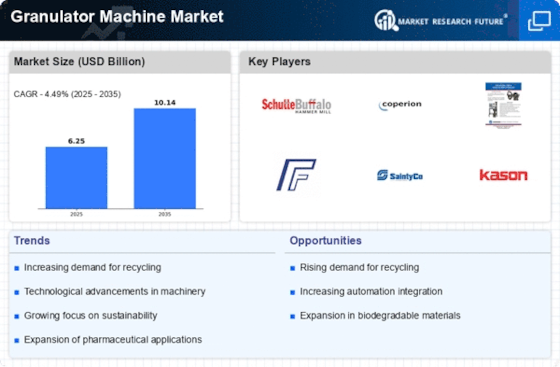

The Granulator Machine Market experiences a notable surge in demand due to the increasing emphasis on recycling and waste management. As environmental regulations tighten, industries are compelled to adopt efficient recycling processes. Granulator machines play a pivotal role in converting waste materials into reusable granules, thereby facilitating the recycling process. In 2025, the recycling sector is projected to grow at a compound annual growth rate of approximately 5.2%, further driving the need for advanced granulation technologies. This trend indicates a robust market potential for granulator machines, as companies seek to enhance their sustainability efforts and reduce waste. The Granulator Machine Market is thus positioned to benefit from this growing focus on recycling, as manufacturers innovate to meet the evolving needs of the market.

Increasing Focus on Energy Efficiency

The Granulator Machine Market is increasingly influenced by the focus on energy efficiency in manufacturing processes. As companies strive to reduce their carbon footprint and operational costs, energy-efficient granulator machines are becoming a priority. In 2025, the market for energy-efficient machinery is expected to grow by approximately 5.5%, reflecting the industry's commitment to sustainability. These machines not only lower energy consumption but also enhance overall productivity, making them attractive to manufacturers. The shift towards energy efficiency aligns with global sustainability goals, further driving the adoption of advanced granulation technologies. This trend indicates that the Granulator Machine Market will likely see a rise in demand for machines that offer both performance and energy savings.

Expansion of Plastics and Polymers Sector

The Granulator Machine Market is significantly influenced by the expansion of the plastics and polymers sector. With the increasing production of plastic materials, there is a corresponding need for granulation processes to ensure efficient manufacturing. In 2025, the plastics industry is expected to witness a growth rate of around 4.5%, which will likely drive the demand for granulator machines. These machines are essential for processing plastic waste and producing granules that can be reused in manufacturing. As companies strive to optimize their production processes and reduce costs, the adoption of granulator machines becomes increasingly vital. This trend suggests that the Granulator Machine Market will continue to thrive as it aligns with the growth trajectory of the plastics sector.

Growth in Pharmaceutical and Chemical Industries

The Granulator Machine Market is poised for growth due to the expanding pharmaceutical and chemical industries. These sectors require precise granulation processes to produce high-quality products. In 2025, the pharmaceutical industry is projected to grow at a rate of around 7%, which will likely increase the demand for granulator machines. These machines are essential for producing granules that meet stringent quality standards in drug manufacturing. Additionally, the chemical industry, with its diverse applications, also relies on granulation for effective processing. This dual demand from both sectors suggests a robust market opportunity for granulator machines. As these industries continue to expand, the Granulator Machine Market is expected to benefit significantly from their growth.

Technological Innovations in Granulation Processes

Technological innovations are reshaping the Granulator Machine Market, leading to enhanced efficiency and performance. The introduction of advanced features such as automation, smart controls, and energy-efficient designs is transforming traditional granulation processes. In 2025, it is anticipated that the market for technologically advanced granulator machines will grow by approximately 6%, as manufacturers seek to improve productivity and reduce operational costs. These innovations not only streamline the granulation process but also contribute to better product quality. As industries increasingly prioritize efficiency and sustainability, the demand for innovative granulator machines is likely to rise. This trend indicates a promising future for the Granulator Machine Market, as companies invest in cutting-edge technologies to remain competitive.