Growing Adoption in Healthcare

The healthcare sector is increasingly recognizing the potential of the Automated 3D Printing Market, particularly in the production of customized medical devices and implants. The ability to create patient-specific solutions, such as prosthetics and surgical models, is transforming the way healthcare providers approach treatment. This trend is supported by data indicating that the medical segment of the 3D printing market is expected to grow significantly, driven by technological advancements and regulatory approvals. As healthcare professionals continue to explore the benefits of personalized medicine, the demand for automated 3D printing solutions is likely to expand, fostering innovation and improving patient outcomes.

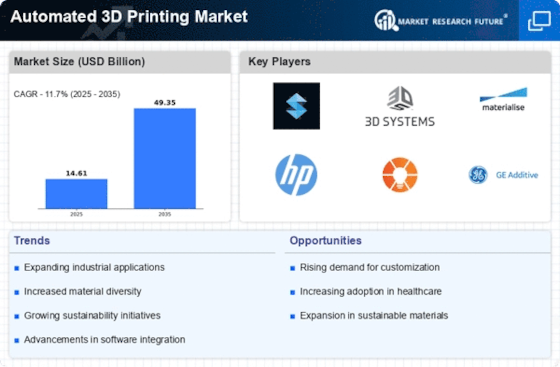

Advancements in Material Science

The evolution of material science is a crucial factor propelling the Automated 3D Printing Market forward. Innovations in materials, including high-performance polymers, metals, and composites, are expanding the capabilities of 3D printing technologies. These advancements enable the production of parts that meet stringent performance criteria, which is essential for industries such as aerospace and medical devices. The introduction of new materials not only enhances the mechanical properties of printed components but also broadens the application scope of 3D printing. As research continues to yield novel materials, the market is likely to witness an increase in adoption rates, as manufacturers seek to leverage these advancements for competitive advantage.

Increased Demand for Prototyping

The Automated 3D Printing Market is experiencing a surge in demand for rapid prototyping across various sectors. Industries such as automotive, aerospace, and consumer goods are increasingly adopting 3D printing technologies to accelerate product development cycles. This shift is driven by the need for faster time-to-market and the ability to create complex geometries that traditional manufacturing methods cannot achieve. According to recent data, the prototyping segment is projected to account for a substantial share of the market, indicating a robust growth trajectory. As companies seek to innovate and reduce costs, the reliance on automated 3D printing for prototyping is likely to intensify, further solidifying its position in the market.

Cost Efficiency and Waste Reduction

Cost efficiency remains a pivotal driver in the Automated 3D Printing Market. The technology allows for the production of parts with minimal material waste, which is particularly appealing in industries where raw material costs are significant. By utilizing additive manufacturing techniques, companies can produce components layer by layer, thereby reducing excess material and energy consumption. This efficiency not only lowers production costs but also aligns with sustainability goals, as companies strive to minimize their environmental footprint. Market analysis suggests that businesses adopting automated 3D printing can achieve cost savings of up to 30% compared to traditional manufacturing methods, making it an attractive option for manufacturers seeking to optimize their operations.

Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies is reshaping the landscape of the Automated 3D Printing Market. The convergence of the Internet of Things (IoT), artificial intelligence, and big data analytics with 3D printing is enhancing operational efficiency and enabling smarter manufacturing processes. This technological synergy allows for real-time monitoring and optimization of production workflows, which can lead to reduced downtime and improved quality control. As manufacturers increasingly adopt these advanced technologies, the market for automated 3D printing is expected to grow, driven by the need for more agile and responsive production systems. The potential for increased productivity and innovation positions automated 3D printing as a key player in the future of manufacturing.