Growth in the Plastics Industry

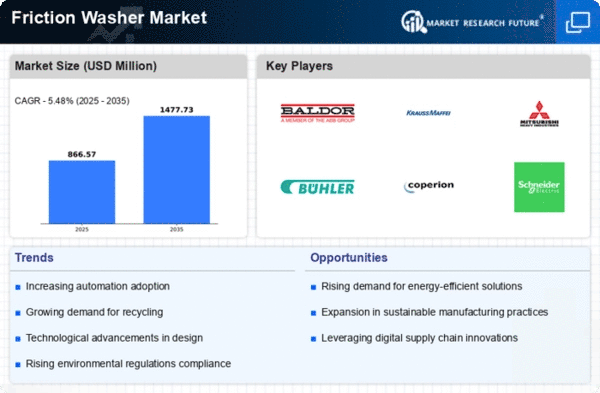

The Global Friction Washer Market Industry is significantly influenced by the growth of the plastics industry, which is experiencing rapid expansion due to increasing consumer demand for plastic products. As plastic production rises, so does the need for efficient recycling processes, where friction washers play a crucial role. The integration of friction washers in recycling facilities enhances the quality and cleanliness of recycled plastics, making them more appealing for reuse in manufacturing. This trend is expected to drive the market value to 1.48 USD Billion by 2035, highlighting the critical role of friction washers in supporting sustainable practices within the plastics sector and reinforcing the Global Friction Washer Market Industry.

Rising Awareness of Environmental Impact

The growing awareness of environmental issues among consumers and businesses is a significant driver for the Global Friction Washer Market Industry. As stakeholders become more conscious of their ecological footprint, there is an increasing demand for efficient recycling solutions that minimize waste. Friction washers are recognized for their ability to improve the quality of recycled materials, thus appealing to environmentally conscious companies. This trend is likely to accelerate market growth, as organizations seek to enhance their sustainability profiles. The emphasis on reducing plastic waste and promoting recycling initiatives positions the Global Friction Washer Market Industry favorably in the context of global environmental efforts.

Increasing Demand for Recycling Solutions

The Global Friction Washer Market Industry experiences a notable surge in demand driven by the increasing emphasis on recycling solutions across various sectors. Industries are increasingly adopting friction washers to enhance the efficiency of plastic recycling processes. This trend is particularly evident in regions where environmental regulations are becoming more stringent, pushing manufacturers to invest in advanced recycling technologies. As a result, the market is projected to reach 0.82 USD Billion in 2024, reflecting a growing awareness of sustainability and resource conservation. The adoption of friction washers not only improves the quality of recycled materials but also contributes to a circular economy, thereby bolstering the Global Friction Washer Market Industry.

Technological Advancements in Washer Design

Technological innovations play a pivotal role in shaping the Global Friction Washer Market Industry. Manufacturers are increasingly focusing on developing advanced friction washers that offer enhanced performance, energy efficiency, and durability. Innovations such as improved motor designs and optimized washing mechanisms are becoming commonplace, allowing for better material processing and reduced operational costs. These advancements are likely to attract a broader customer base, including those in sectors such as automotive and packaging. As a result, the market is expected to witness a compound annual growth rate of 5.49% from 2025 to 2035, indicating a robust trajectory for the Global Friction Washer Market Industry.

Regulatory Support for Sustainable Practices

Regulatory frameworks promoting sustainable practices are increasingly shaping the Global Friction Washer Market Industry. Governments worldwide are implementing policies that encourage recycling and waste management, thereby creating a favorable environment for friction washer adoption. These regulations often mandate the use of advanced recycling technologies, which friction washers provide. As industries strive to comply with these regulations, the demand for friction washers is likely to rise. This regulatory support not only enhances market growth but also aligns with global sustainability goals, fostering a more environmentally responsible approach to manufacturing and waste management within the Global Friction Washer Market Industry.