Rising Demand in Oil and Gas Sector

The Friction Reducer Market is experiencing a notable surge in demand, particularly within the oil and gas sector. As exploration and production activities intensify, the need for efficient drilling fluids that minimize friction becomes paramount. In 2025, the oil and gas industry is projected to account for a substantial share of the friction reducer market, driven by the increasing complexity of drilling operations. Enhanced performance and cost-effectiveness of friction reducers are critical for optimizing drilling efficiency, thereby reducing operational costs. This trend indicates a robust growth trajectory for the friction reducer market, as companies seek to improve their drilling processes and maximize resource extraction.

Increasing Focus on Energy Efficiency

The Friction Reducer Market is witnessing a paradigm shift towards energy efficiency, as industries strive to reduce operational costs and environmental impact. The demand for friction reducers that enhance energy efficiency in various applications, including transportation and manufacturing, is on the rise. In 2025, the market is likely to see a significant increase in the adoption of friction reducers that not only improve performance but also contribute to sustainability goals. This trend suggests that companies are increasingly prioritizing the integration of energy-efficient solutions, thereby fostering growth in the friction reducer market as they seek to optimize their operations.

Growth in Hydraulic Fracturing Activities

The Friction Reducer Market is significantly influenced by the expansion of hydraulic fracturing activities. As energy demands rise, hydraulic fracturing has become a prevalent method for extracting oil and gas from unconventional reservoirs. The friction reducer market is poised for growth, as these additives play a crucial role in reducing friction during the fracturing process. In 2025, the hydraulic fracturing segment is expected to represent a considerable portion of the overall market, driven by the need for efficient and effective fracturing fluids. This growth is indicative of the increasing reliance on advanced technologies to enhance extraction processes, thereby propelling the friction reducer market forward.

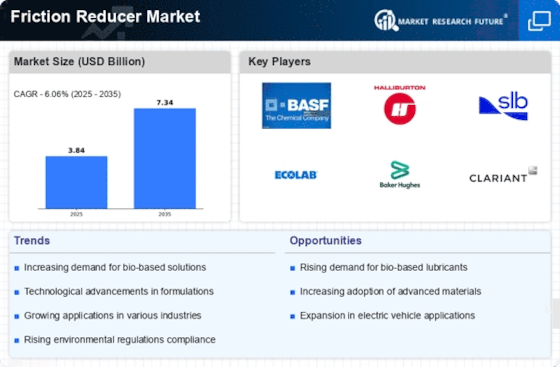

Technological Innovations in Friction Reducers

The Friction Reducer Market is benefiting from ongoing technological innovations that enhance the performance and applicability of friction reducers. Advances in chemical formulations and material science are leading to the development of more effective friction-reducing agents. In 2025, the market is expected to see a rise in the introduction of novel friction reducers that cater to specific industry needs, such as high-temperature applications or environmentally friendly options. This innovation-driven growth indicates that companies are investing in research and development to create tailored solutions, thereby expanding the potential applications of friction reducers across various sectors.

Regulatory Support for Enhanced Performance Materials

The Friction Reducer Market is positively impacted by regulatory support aimed at promoting the use of enhanced performance materials. Governments are increasingly recognizing the importance of efficient materials in reducing energy consumption and environmental impact. In 2025, regulations that encourage the adoption of advanced friction reducers are likely to drive market growth, as industries seek compliance while improving operational efficiency. This regulatory landscape suggests a favorable environment for the friction reducer market, as companies align their product offerings with sustainability and performance standards, thereby enhancing their competitive edge.