Growing Automotive Production

The resurgence of automotive production is a key driver for the Foundry Binder Market. As vehicle manufacturers ramp up production to meet consumer demand, the need for high-quality castings and components becomes paramount. Data indicates that the automotive sector accounts for a significant portion of foundry output, with projections suggesting a steady increase in vehicle production in the coming years. This growth is likely to stimulate demand for advanced foundry binders that can withstand the rigorous requirements of automotive applications. Consequently, the Foundry Binder Market is poised for expansion, as manufacturers seek to optimize their processes and enhance product quality.

Increased Investment in Infrastructure

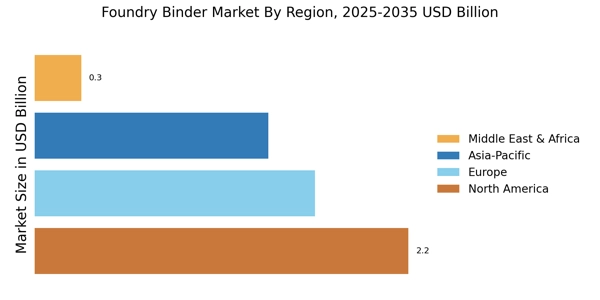

The ongoing investment in infrastructure development across various regions is significantly impacting the Foundry Binder Market. Governments and private sectors are allocating substantial budgets for construction and renovation projects, which in turn increases the demand for castings and components produced using foundry binders. Recent reports indicate that infrastructure spending is projected to reach trillions of dollars in the coming years, creating a robust market for foundry products. This surge in demand for construction materials is likely to drive the growth of the foundry binder market, as manufacturers seek efficient and high-performance binders to meet the needs of the infrastructure sector.

Rising Demand for Lightweight Materials

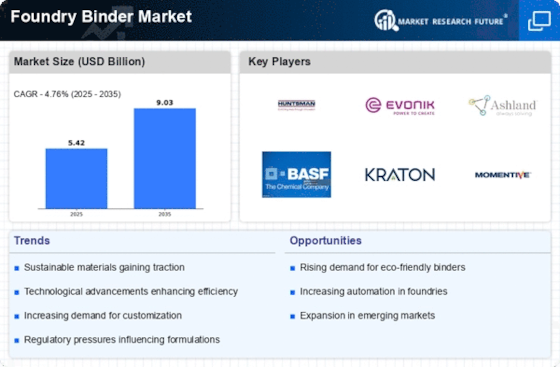

The increasing demand for lightweight materials in various industries, particularly in automotive and aerospace, is driving the Foundry Binder Market. Manufacturers are seeking to reduce weight without compromising strength, leading to a surge in the use of advanced foundry binders. This trend is supported by data indicating that lightweight materials can enhance fuel efficiency and reduce emissions. As a result, the foundry binder market is expected to witness substantial growth, with projections suggesting a compound annual growth rate of around 5% over the next few years. The shift towards lightweight solutions is likely to influence the types of binders used, emphasizing the need for innovation in the Foundry Binder Market.

Technological Innovations in Binder Formulations

Technological advancements in binder formulations are reshaping the Foundry Binder Market. Innovations such as the development of eco-friendly binders and improved curing processes are gaining traction among manufacturers. These advancements not only enhance the performance of foundry binders but also align with sustainability goals. For instance, the introduction of water-soluble binders has shown promising results in reducing emissions during the casting process. As industries increasingly prioritize environmental considerations, the demand for innovative binder solutions is expected to rise. This trend suggests that the Foundry Binder Market will continue to evolve, driven by the need for more efficient and sustainable binder technologies.

Shift Towards Sustainable Manufacturing Practices

The shift towards sustainable manufacturing practices is profoundly influencing the Foundry Binder Market. As industries face increasing pressure to reduce their environmental footprint, the demand for sustainable foundry binders is on the rise. Manufacturers are exploring alternatives that minimize waste and emissions, such as bio-based binders and recyclable materials. Recent studies suggest that the adoption of sustainable practices can lead to cost savings and improved market competitiveness. This trend indicates that the Foundry Binder Market will likely experience a transformation, as companies prioritize eco-friendly solutions to meet regulatory requirements and consumer expectations.