Increased Regulatory Standards

The Filter Coating Market is significantly influenced by the rise in regulatory standards aimed at improving environmental sustainability and product safety. Governments and regulatory bodies are implementing stricter guidelines regarding emissions and waste management, compelling manufacturers to adopt advanced filter coatings that comply with these regulations. For instance, the introduction of new environmental policies has led to a surge in demand for coatings that minimize harmful emissions in industrial applications. This shift not only enhances the market's growth potential but also encourages innovation in coating technologies. As companies strive to align with these evolving standards, the Filter Coating Market is expected to witness a robust expansion, driven by the need for compliance and sustainability.

Expansion of End-User Industries

The Filter Coating Market is significantly impacted by the expansion of end-user industries, including automotive, aerospace, and industrial manufacturing. As these sectors continue to grow, the demand for effective filtration solutions is expected to rise correspondingly. For instance, the automotive industry is increasingly incorporating advanced filter coatings to enhance engine performance and reduce emissions. Market projections indicate that the automotive sector alone could contribute to a 10% increase in filter coating demand over the next five years. This expansion across various industries not only drives the Filter Coating Market but also encourages innovation and diversification in coating technologies, ultimately leading to a more competitive market landscape.

Growing Awareness of Health and Safety

The Filter Coating Market is witnessing a surge in awareness regarding health and safety, particularly in sectors such as food and beverage, pharmaceuticals, and water treatment. As consumers and regulatory agencies emphasize the importance of safe and clean products, manufacturers are increasingly turning to advanced filter coatings that ensure product integrity and safety. This heightened focus on health and safety standards is driving the demand for coatings that can effectively filter contaminants and improve product quality. Market analysis suggests that this trend could lead to a growth rate of around 7% in the filter coating segment over the next few years. Consequently, the Filter Coating Market is poised for expansion as companies prioritize health and safety in their product offerings.

Rising Demand for High-Performance Coatings

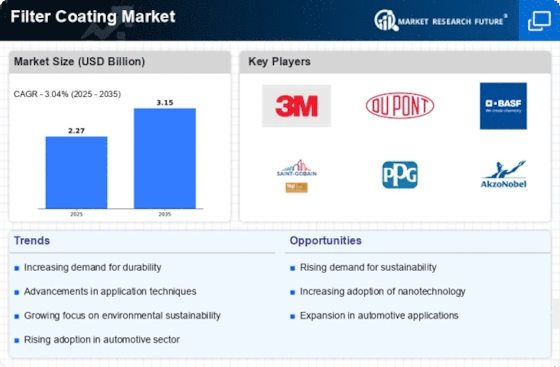

The Filter Coating Market experiences a notable increase in demand for high-performance coatings, driven by the need for enhanced durability and efficiency in various applications. Industries such as automotive, aerospace, and electronics are increasingly adopting advanced filter coatings to improve product longevity and performance. According to recent data, the market for high-performance coatings is projected to grow at a compound annual growth rate of approximately 6% over the next five years. This trend indicates a shift towards more specialized coatings that can withstand extreme conditions, thereby propelling the Filter Coating Market forward. As manufacturers seek to meet stringent regulatory standards and consumer expectations, the emphasis on high-performance coatings is likely to intensify, further solidifying their role in the market.

Technological Innovations in Coating Processes

Technological innovations play a pivotal role in shaping the Filter Coating Market, as advancements in coating processes lead to improved efficiency and effectiveness. The introduction of novel application techniques, such as electrostatic spraying and advanced curing methods, enhances the performance of filter coatings. These innovations not only reduce production costs but also improve the quality and consistency of the coatings applied. Recent studies indicate that the adoption of these technologies could increase market penetration by approximately 15% over the next few years. As manufacturers continue to invest in research and development, the Filter Coating Market is likely to benefit from enhanced product offerings and increased competitiveness.