Growing Construction Sector

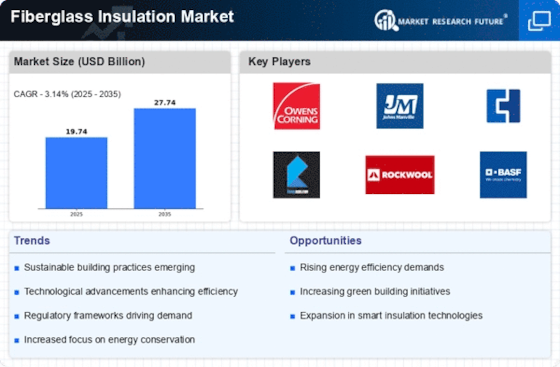

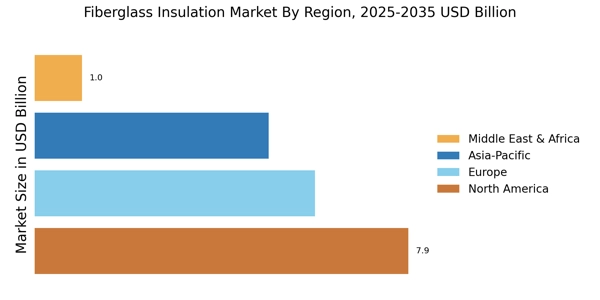

The expansion of the construction sector is a significant catalyst for the Fiberglass Insulation Market. With urbanization and population growth driving the need for new residential and commercial buildings, the demand for effective insulation solutions is likely to increase. Recent statistics indicate that the construction industry is projected to grow at a compound annual growth rate of approximately 5% over the next few years. This growth is expected to enhance the market for fiberglass insulation, as builders seek materials that offer both performance and cost-effectiveness. The versatility of fiberglass insulation in various applications, from attics to walls, further supports its adoption in new construction projects.

Rising Energy Efficiency Standards

The increasing emphasis on energy efficiency standards across various regions appears to be a pivotal driver for the Fiberglass Insulation Market. Governments and regulatory bodies are implementing stringent building codes that mandate higher insulation performance. This trend is likely to propel the demand for fiberglass insulation, as it is recognized for its superior thermal performance and energy-saving capabilities. According to recent data, buildings equipped with fiberglass insulation can achieve energy savings of up to 30% compared to those without. As energy costs continue to rise, the adoption of fiberglass insulation is expected to grow, aligning with the global push towards sustainable construction practices.

Increased Awareness of Indoor Air Quality

The rising awareness of indoor air quality and its impact on health is influencing the Fiberglass Insulation Market. Consumers and builders are increasingly recognizing the importance of using materials that contribute to a healthier indoor environment. Fiberglass insulation is known for its non-combustibility and resistance to mold and mildew, making it a preferred choice for those concerned about air quality. Market data suggests that the demand for insulation products that enhance indoor air quality is on the rise, with fiberglass insulation being a key player in this trend. As more individuals prioritize health and wellness in their living spaces, the market for fiberglass insulation is likely to expand.

Technological Innovations in Insulation Materials

Technological advancements in insulation materials are reshaping the Fiberglass Insulation Market. Innovations such as improved manufacturing processes and the development of high-performance fiberglass products are enhancing the effectiveness and efficiency of insulation solutions. These advancements not only improve thermal resistance but also reduce the environmental impact of production. Recent developments indicate that new fiberglass insulation products can achieve higher R-values, which measure thermal resistance, thus providing better energy efficiency. As technology continues to evolve, the market is expected to witness a surge in demand for advanced fiberglass insulation solutions that meet the needs of modern construction.

Government Incentives for Energy-Efficient Solutions

Government incentives aimed at promoting energy-efficient solutions are likely to bolster the Fiberglass Insulation Market. Various programs and tax credits are being introduced to encourage the use of insulation materials that enhance energy efficiency in buildings. These incentives can significantly reduce the upfront costs associated with installing fiberglass insulation, making it a more attractive option for homeowners and builders alike. Market analysis indicates that regions with robust incentive programs experience higher adoption rates of fiberglass insulation. As these initiatives continue to gain traction, the market for fiberglass insulation is expected to benefit from increased consumer interest and investment in energy-efficient building practices.