North America : Market Leader in MRO Services

North America is poised to maintain its leadership in the Fabric Production Equipment MRO services market, holding a significant market share of 2.6 in 2024. The region's growth is driven by robust manufacturing capabilities, technological advancements, and increasing demand for automation in production processes. Regulatory support for sustainable practices further enhances market dynamics, encouraging investments in modern MRO solutions.

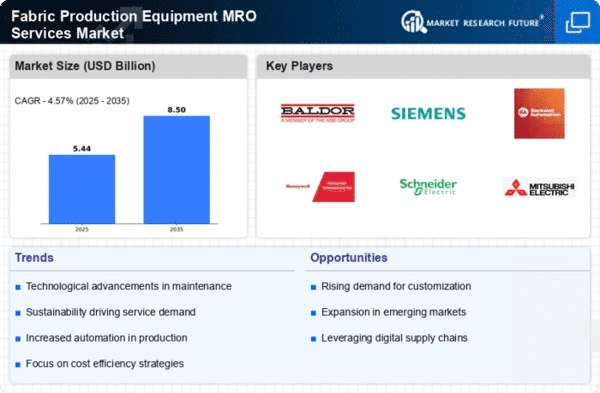

The competitive landscape in North America is characterized by the presence of key players such as Baldor Electric Company, Rockwell Automation, and Honeywell International. These companies are leveraging innovative technologies to improve efficiency and reduce downtime in fabric production. The U.S. remains the leading country, supported by a strong industrial base and a focus on enhancing operational efficiencies through advanced MRO services.

Europe : Emerging Market with Growth Potential

Europe's Fabric Production Equipment MRO services market is valued at 1.5, reflecting a growing demand for efficient maintenance solutions. The region is witnessing a shift towards automation and smart manufacturing, driven by regulatory frameworks promoting sustainability and innovation. The European Union's initiatives to enhance industrial competitiveness are pivotal in shaping market trends, fostering a conducive environment for MRO service providers.

Leading countries such as Germany, France, and Italy are at the forefront of this market, with significant investments in advanced manufacturing technologies. Key players like Siemens AG and Schneider Electric are actively enhancing their service offerings to meet the evolving needs of the fabric production sector. The competitive landscape is marked by collaborations and partnerships aimed at delivering integrated MRO solutions, ensuring operational excellence.

Asia-Pacific : Rapid Growth in Emerging Economies

The Asia-Pacific region, with a market size of 1.3, is rapidly emerging as a key player in the Fabric Production Equipment MRO services market. The growth is fueled by increasing industrialization, rising demand for textiles, and a shift towards automation in manufacturing processes. Government initiatives aimed at enhancing manufacturing capabilities and infrastructure are also significant drivers of market expansion in this region.

Countries like China, Japan, and India are leading the charge, with substantial investments in modernizing their manufacturing sectors. The competitive landscape features major players such as Mitsubishi Electric and Yaskawa Electric, who are focusing on innovative solutions to improve efficiency and reduce operational costs. The region's diverse market dynamics present both challenges and opportunities for MRO service providers, making it a vibrant area for growth.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, with a market size of 0.8, presents significant growth opportunities in the Fabric Production Equipment MRO services market. The region is experiencing a gradual shift towards industrialization, driven by government initiatives aimed at diversifying economies and enhancing manufacturing capabilities. Increased investments in infrastructure and technology are expected to catalyze market growth in the coming years.

Countries such as South Africa and the UAE are leading the way in adopting advanced manufacturing practices. The competitive landscape is evolving, with both local and international players seeking to establish a foothold in this emerging market. Key players are focusing on tailored MRO solutions to meet the unique needs of the region, positioning themselves for future growth.