Rising Demand for Efficient Production

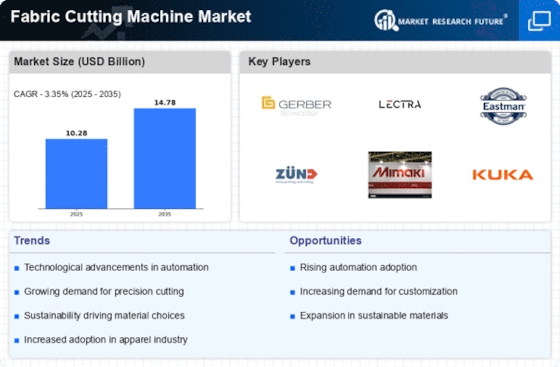

The Fabric Cutting Machine Market is experiencing a notable surge in demand for efficient production processes. As manufacturers strive to enhance productivity and reduce operational costs, the adoption of advanced fabric cutting machines becomes increasingly appealing. According to recent data, the market is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This growth is driven by the need for precision and speed in cutting operations, which are essential for meeting the fast-paced requirements of the textile and apparel sectors. Furthermore, the integration of automation in fabric cutting machines is likely to streamline workflows, thereby improving overall efficiency. Consequently, manufacturers are investing in innovative technologies that not only optimize production but also ensure high-quality output, thereby reinforcing the significance of this driver in the Fabric Cutting Machine Market.

Customization and Personalization Trends

The Fabric Cutting Machine Market is witnessing a growing trend towards customization and personalization. As consumers increasingly seek unique and tailored products, manufacturers are compelled to adapt their production processes accordingly. This trend is particularly evident in the fashion and home textiles sectors, where bespoke designs are gaining traction. Recent market analyses indicate that the demand for customizable fabric cutting solutions is expected to rise, with a projected growth rate of around 6% annually. This shift necessitates the development of cutting machines that can efficiently handle small batch sizes and intricate designs. Consequently, manufacturers are investing in versatile cutting technologies that allow for rapid adjustments and modifications. The ability to offer personalized products not only enhances customer satisfaction but also positions companies competitively within the Fabric Cutting Machine Market.

Growth of the Apparel and Textile Industry

The Fabric Cutting Machine Market is significantly influenced by the growth of the apparel and textile industry. As consumer preferences evolve and demand for diverse clothing options increases, manufacturers are compelled to adopt advanced cutting technologies to keep pace. The apparel sector is projected to expand at a robust rate, with estimates suggesting a growth rate of around 5% annually. This expansion necessitates efficient fabric cutting solutions that can handle varying fabric types and thicknesses. Consequently, the demand for high-performance fabric cutting machines is likely to rise, as manufacturers seek to optimize their production processes. Furthermore, the increasing trend of fast fashion, characterized by rapid design-to-market cycles, further emphasizes the need for efficient cutting solutions. Thus, the growth trajectory of the apparel and textile industry serves as a crucial driver for the Fabric Cutting Machine Market.

Technological Advancements in Cutting Equipment

Technological advancements play a pivotal role in shaping the Fabric Cutting Machine Market. The introduction of computer numerical control (CNC) technology and laser cutting systems has revolutionized the way fabrics are cut, offering unparalleled precision and versatility. These innovations enable manufacturers to execute complex designs with ease, thereby catering to the diverse needs of the fashion and textile industries. Recent statistics indicate that the market for CNC fabric cutting machines is expected to witness substantial growth, driven by their ability to minimize waste and enhance production efficiency. Additionally, the integration of smart technologies, such as IoT and AI, into cutting machines is anticipated to further elevate operational capabilities. As a result, manufacturers are increasingly inclined to invest in state-of-the-art cutting equipment, which is likely to propel the Fabric Cutting Machine Market forward.

Focus on Sustainability and Eco-Friendly Practices

Sustainability has emerged as a critical focus within the Fabric Cutting Machine Market. As environmental concerns gain prominence, manufacturers are increasingly adopting eco-friendly practices in their production processes. This shift is reflected in the growing demand for fabric cutting machines that minimize waste and utilize sustainable materials. Recent data suggests that the market for sustainable cutting technologies is on the rise, with a projected growth rate of approximately 7% over the next few years. Manufacturers are exploring innovative solutions, such as waterjet cutting and laser cutting, which not only reduce material waste but also lower energy consumption. This emphasis on sustainability aligns with the broader industry trend towards responsible manufacturing, making it a vital driver for the Fabric Cutting Machine Market. As companies strive to meet regulatory standards and consumer expectations, the integration of sustainable practices is likely to shape future market dynamics.