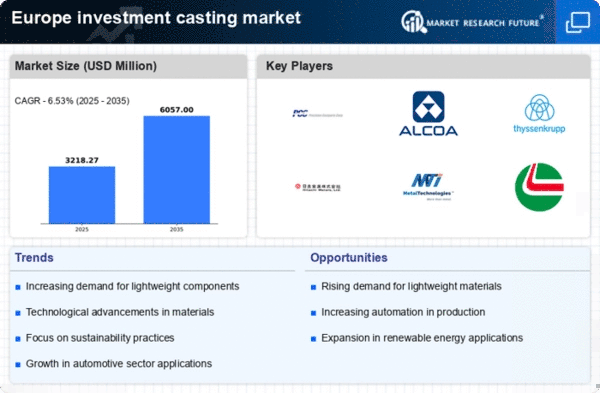

Growth in Aerospace Applications

The aerospace industry in Europe is increasingly relying on investment casting for the production of complex and lightweight components. This trend is driven by the need for enhanced performance and fuel efficiency in aircraft design. Investment casting market is expected to benefit significantly from this growth, as it allows for the creation of intricate geometries that are often required in aerospace applications. In 2025, the aerospace sector is anticipated to represent around 25% of the overall investment casting demand in Europe. Furthermore, the ongoing advancements in materials technology, such as the use of superalloys, are likely to further propel the investment casting market, as manufacturers seek to optimize performance and reduce weight in aircraft components.

Rising Demand in Automotive Sector

The automotive sector in Europe is experiencing a notable surge in demand for lightweight and high-strength components, which are essential for enhancing fuel efficiency and performance. Investment casting market plays a crucial role in supplying precision-engineered parts that meet these requirements. In 2025, the automotive industry is projected to account for approximately 30% of the total demand for investment castings in Europe. This trend is driven by the increasing adoption of electric vehicles (EVs) and stringent emissions regulations, compelling manufacturers to seek advanced materials and manufacturing techniques. As a result, the investment casting market is likely to witness substantial growth, as it provides the necessary solutions to meet the evolving needs of the automotive sector.

Increased Focus on Renewable Energy

The shift towards renewable energy sources in Europe is driving demand for investment casting in the production of components for wind turbines and other energy systems. The investment casting market is poised to capitalize on this trend, as it provides the necessary precision and durability required for energy applications. In 2025, it is estimated that the renewable energy sector will account for approximately 15% of the total investment casting market in Europe. This growth is fueled by government initiatives aimed at promoting sustainable energy solutions, which in turn creates opportunities for manufacturers specializing in investment casting. As the demand for renewable energy components continues to rise, the investment casting market is likely to expand its footprint in this sector.

Technological Innovations in Manufacturing

Technological innovations are reshaping the landscape of the investment casting market in Europe. The adoption of advanced manufacturing techniques, such as 3D printing and automation, is enhancing production efficiency and reducing lead times. These innovations enable manufacturers to produce complex geometries with greater precision, thereby meeting the stringent quality standards required in various industries. In 2025, it is projected that the integration of these technologies will lead to a 20% increase in productivity within the investment casting market. As companies strive to remain competitive, the continuous evolution of manufacturing technologies is likely to drive further growth and investment in the investment casting market.

Regulatory Compliance and Quality Standards

The investment casting market in Europe is significantly influenced by stringent regulatory compliance and quality standards across various sectors. Industries such as automotive, aerospace, and energy are subject to rigorous regulations that dictate the quality and safety of components. This necessitates a robust investment casting process that adheres to these standards. In 2025, it is anticipated that compliance with these regulations will drive a 10% increase in demand for high-quality investment castings. Manufacturers are increasingly investing in quality assurance processes and certifications to meet these requirements, thereby enhancing their competitiveness in the investment casting market. As regulations evolve, the focus on quality and compliance is likely to remain a key driver for growth.