Emergence of Advanced Materials

The emergence of advanced materials is reshaping the landscape of the Etching Machine Market. As industries increasingly adopt materials such as ceramics, composites, and nanomaterials, the demand for specialized etching machines capable of processing these materials is on the rise. In 2025, the market for etching machines designed for advanced materials is anticipated to grow by approximately 8%, reflecting the need for precision in applications ranging from aerospace to medical devices. This trend indicates a shift towards more sophisticated etching technologies that can accommodate the unique properties of these materials, thereby driving innovation and growth within the Etching Machine Market.

Expansion of the Automotive Sector

The automotive sector's expansion is significantly influencing the Etching Machine Market. With the increasing complexity of automotive components, manufacturers are adopting advanced etching techniques to enhance precision and efficiency. In 2025, the automotive industry is expected to contribute notably to the etching machine market, with a projected growth rate of around 6% annually. This growth is driven by the rising demand for electric vehicles, which require intricate etching processes for battery components and electronic systems. As automotive manufacturers seek to improve production capabilities and reduce costs, the adoption of advanced etching machines is likely to become a key strategy, thereby fostering growth within the Etching Machine Market.

Increased Focus on Miniaturization

The trend towards miniaturization in various industries is significantly impacting the Etching Machine Market. As products become smaller and more compact, the need for precise etching processes that can accommodate intricate designs is paramount. In 2025, the miniaturization trend is expected to drive a growth rate of around 7% in the etching machine market, particularly in sectors such as consumer electronics and telecommunications. This demand for smaller components necessitates the development of advanced etching technologies that can deliver high precision and efficiency. Consequently, manufacturers are likely to invest in innovative etching solutions to meet the challenges posed by miniaturization, thereby enhancing the overall growth of the Etching Machine Market.

Government Regulations and Standards

Government regulations and standards are playing a crucial role in shaping the Etching Machine Market. As industries face increasing scrutiny regarding environmental impact and product quality, compliance with stringent regulations is becoming essential. In 2025, the market is expected to witness a shift towards etching machines that meet higher environmental standards, potentially increasing the demand for eco-friendly technologies. This regulatory landscape is likely to drive innovation as manufacturers seek to develop etching solutions that not only comply with regulations but also enhance operational efficiency. As a result, the Etching Machine Market may experience growth fueled by the need for compliance and sustainability in manufacturing processes.

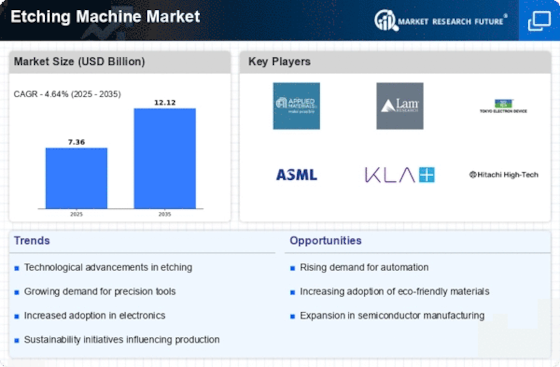

Rising Demand in Electronics Manufacturing

The Etching Machine Market is experiencing a surge in demand driven by the rapid growth of the electronics manufacturing sector. As electronic devices become increasingly sophisticated, the need for precise etching processes has intensified. In 2025, the electronics sector is projected to account for a substantial share of the etching machine market, with an estimated value exceeding 2 billion USD. This growth is attributed to the rising production of semiconductors and printed circuit boards, which require advanced etching techniques to ensure high-quality performance. Consequently, manufacturers are investing in innovative etching technologies to meet the evolving needs of the electronics industry, thereby propelling the Etching Machine Market forward.