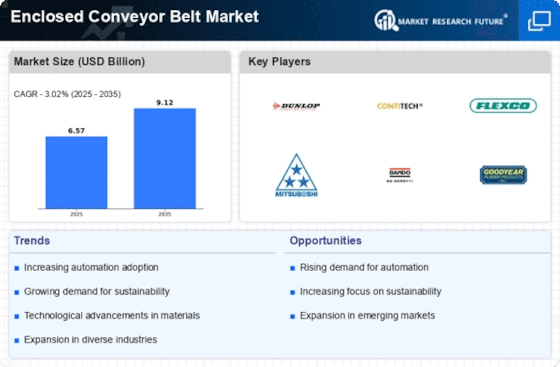

Increased Demand for Automation

The Enclosed Conveyor Belt Market is experiencing a notable surge in demand for automation across various sectors. Industries such as manufacturing, food processing, and mining are increasingly adopting automated systems to enhance efficiency and reduce labor costs. This trend is driven by the need for streamlined operations and improved productivity. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 9% over the next five years. As companies seek to optimize their supply chains, the integration of enclosed conveyor belts becomes essential, facilitating the seamless movement of materials while minimizing human intervention. This shift towards automation not only boosts operational efficiency but also aligns with the broader trend of digital transformation in industrial processes.

Rising Focus on Workplace Safety

Workplace safety remains a paramount concern in the Enclosed Conveyor Belt Market. The implementation of enclosed conveyor systems significantly reduces the risk of accidents associated with material handling. These systems are designed to contain materials, preventing spills and exposure to hazardous substances. As industries face increasing scrutiny regarding safety standards, the demand for enclosed conveyor belts is likely to rise. Regulatory bodies are enforcing stricter safety regulations, compelling companies to invest in safer material handling solutions. The market for safety equipment and systems is expected to grow, with enclosed conveyor belts playing a crucial role in ensuring compliance. This focus on safety not only protects workers but also enhances operational reliability, making it a key driver in the market.

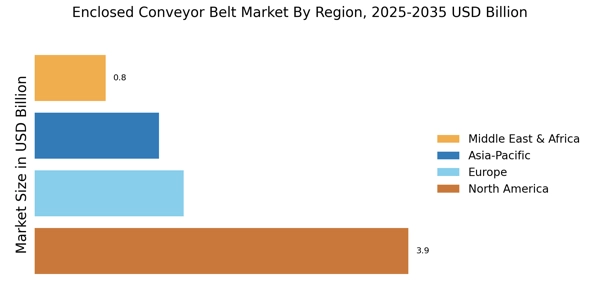

Expansion of E-commerce and Logistics

The rapid expansion of e-commerce and logistics sectors is significantly influencing the Enclosed Conveyor Belt Market. As online shopping continues to gain traction, warehouses and distribution centers are under pressure to optimize their operations. Enclosed conveyor belts offer an efficient solution for transporting goods within these facilities, ensuring quick and safe delivery. Recent statistics indicate that the e-commerce market is projected to reach over 6 trillion dollars by 2024, necessitating advanced material handling systems. The need for speed and efficiency in logistics operations drives the adoption of enclosed conveyor systems, which can handle various product types and sizes. This trend is expected to propel the growth of the enclosed conveyor belt market, as companies seek to enhance their supply chain capabilities.

Sustainability and Environmental Considerations

Sustainability is becoming a critical driver in the Enclosed Conveyor Belt Market as companies strive to reduce their environmental footprint. The demand for eco-friendly materials and energy-efficient systems is on the rise, prompting manufacturers to innovate. Enclosed conveyor belts made from recyclable materials and designed for energy efficiency are gaining traction. Recent studies suggest that the market for sustainable conveyor systems is expected to grow by 15% annually as businesses prioritize green initiatives. This shift not only aligns with corporate social responsibility goals but also meets the expectations of environmentally conscious consumers. As sustainability becomes a core business strategy, the enclosed conveyor belt market is likely to see increased investment and innovation in eco-friendly solutions.

Technological Advancements in Material Handling

Technological advancements are reshaping the Enclosed Conveyor Belt Market, leading to the development of innovative solutions that enhance performance and efficiency. The integration of smart technologies, such as IoT and AI, into conveyor systems allows for real-time monitoring and predictive maintenance. These advancements not only improve operational efficiency but also reduce downtime and maintenance costs. The market for smart conveyor systems is anticipated to grow significantly, driven by the increasing need for data-driven decision-making in material handling. Companies are investing in these technologies to gain a competitive edge, making the adoption of advanced enclosed conveyor belts a strategic priority. This trend indicates a shift towards more intelligent and responsive material handling solutions.