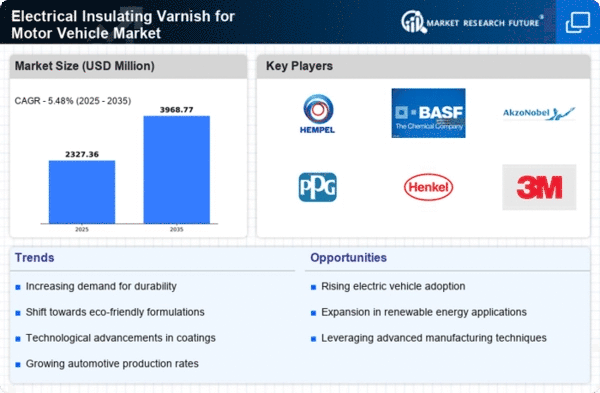

Market Growth Projections

The Global Electrical Insulating Varnish for Motor Vehicle Market Industry is projected to experience robust growth over the next decade. With an anticipated market value of 2.21 USD Billion in 2024, the industry is expected to double to 4.41 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 6.49% from 2025 to 2035, indicating a strong demand for electrical insulating varnishes driven by various factors such as the rise of electric vehicles, technological advancements, and regulatory pressures.

Stringent Regulatory Standards

The implementation of stringent regulatory standards regarding vehicle emissions and energy efficiency is a significant driver for the Global Electrical Insulating Varnish for Motor Vehicle Market Industry. Governments worldwide are enforcing regulations that necessitate the use of high-performance insulating materials in motor vehicles. These regulations aim to reduce environmental impact and enhance vehicle safety. As a result, manufacturers are increasingly investing in high-quality insulating varnishes that meet these standards. This trend is expected to bolster market growth, as compliance with regulations often requires the adoption of advanced insulating technologies.

Growth in Automotive Production

The expansion of automotive production globally is a crucial factor propelling the Global Electrical Insulating Varnish for Motor Vehicle Market Industry. As vehicle production increases, so does the demand for various components, including electrical insulating varnishes. Emerging markets, particularly in Asia-Pacific, are witnessing a surge in automotive manufacturing, driven by rising consumer demand and economic growth. This increase in production not only boosts the need for insulating materials but also encourages manufacturers to innovate and improve their product offerings. Consequently, the market is poised for substantial growth in the coming years.

Rising Demand for Electric Vehicles

The increasing adoption of electric vehicles (EVs) is a primary driver for the Global Electrical Insulating Varnish for Motor Vehicle Market Industry. As manufacturers focus on enhancing the performance and longevity of electric motors, the demand for high-quality insulating varnishes is expected to rise. In 2024, the market is projected to reach 2.21 USD Billion, reflecting the growing need for effective insulation solutions that can withstand the unique challenges posed by electric drivetrains. This trend is likely to continue as the global automotive industry shifts towards electrification, potentially doubling the market size to 4.41 USD Billion by 2035.

Increased Focus on Energy Efficiency

The growing emphasis on energy efficiency in the automotive sector is a notable driver for the Global Electrical Insulating Varnish for Motor Vehicle Market Industry. As consumers and manufacturers alike prioritize sustainability, the demand for insulating varnishes that enhance energy efficiency is on the rise. These varnishes play a critical role in reducing energy losses in electric motors, thereby improving overall vehicle performance. This trend aligns with global efforts to minimize carbon footprints and promote sustainable practices within the automotive industry. As energy efficiency becomes a focal point, the market for electrical insulating varnishes is expected to expand significantly.

Technological Advancements in Coating Materials

Innovations in coating technologies are significantly influencing the Global Electrical Insulating Varnish for Motor Vehicle Market Industry. The development of advanced insulating varnishes that offer superior thermal stability, chemical resistance, and electrical insulation properties is becoming increasingly prevalent. These advancements not only enhance the performance of electric motors but also contribute to energy efficiency. As manufacturers seek to comply with stringent environmental regulations, the demand for eco-friendly insulating varnishes is likely to grow. This shift towards advanced materials could drive the market's compound annual growth rate (CAGR) to 6.49% from 2025 to 2035.