Integration of Smart Technologies

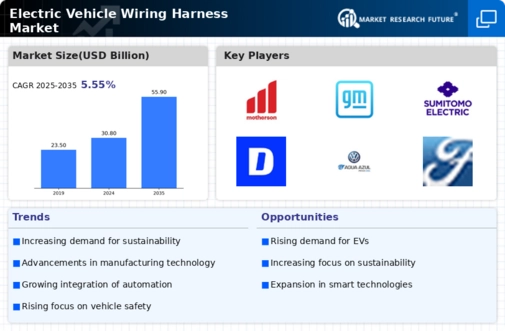

The Electric Vehicle Wiring Harness Market is increasingly influenced by the integration of smart technologies. The rise of connected vehicles necessitates advanced wiring harnesses that can support various electronic systems, including infotainment, navigation, and driver assistance features. This trend is expected to drive the demand for more complex wiring solutions, as vehicles become more reliant on electronic components. According to recent estimates, the market for smart wiring harnesses is anticipated to grow significantly, with projections indicating a compound annual growth rate of around 12% over the next few years. The incorporation of smart technologies not only enhances vehicle functionality but also improves safety and user experience, making it a critical driver in the Electric Vehicle Wiring Harness Market.

Regulatory Support and Incentives

The Electric Vehicle Wiring Harness Market is significantly influenced by regulatory support and incentives aimed at promoting electric vehicle adoption. Governments worldwide are implementing policies that encourage the production and purchase of electric vehicles, which in turn drives the demand for efficient wiring harnesses. For instance, tax credits and subsidies for electric vehicle buyers are creating a favorable market environment. Additionally, stringent emissions regulations are compelling manufacturers to transition towards electric mobility solutions, further boosting the wiring harness market. It is estimated that these regulatory measures could lead to a market growth of approximately 20% over the next few years. As such, the supportive regulatory landscape is a crucial driver for the Electric Vehicle Wiring Harness Market.

Growing Consumer Demand for Sustainability

The Electric Vehicle Wiring Harness Market is witnessing a notable shift driven by growing consumer demand for sustainability. As environmental concerns become more pronounced, consumers are increasingly favoring electric vehicles over traditional combustion engines. This shift is prompting manufacturers to invest in sustainable practices, including the use of eco-friendly materials in wiring harness production. Reports suggest that the market for sustainable wiring solutions is set to expand, with a projected growth rate of 10% annually. Additionally, the emphasis on reducing carbon footprints is leading to innovations in recycling and waste management within the wiring harness sector. This alignment with consumer values is likely to bolster the Electric Vehicle Wiring Harness Market, as companies strive to meet the expectations of environmentally conscious consumers.

Expansion of Electric Vehicle Infrastructure

The Electric Vehicle Wiring Harness Market is poised for growth due to the expansion of electric vehicle infrastructure. The development of charging stations and maintenance facilities is essential for supporting the increasing number of electric vehicles on the road. This infrastructure expansion necessitates the installation of advanced wiring systems that can handle the demands of electric vehicle technology. Recent data indicates that investments in charging infrastructure are expected to reach billions of dollars in the coming years, which will likely stimulate demand for wiring harnesses. Furthermore, as more consumers adopt electric vehicles, the need for reliable and efficient wiring solutions will become even more pronounced. Thus, the expansion of electric vehicle infrastructure serves as a vital driver for the Electric Vehicle Wiring Harness Market.

Technological Advancements in Wiring Systems

The Electric Vehicle Wiring Harness Market is experiencing a surge in technological advancements that enhance the efficiency and reliability of wiring systems. Innovations such as lightweight materials and improved insulation techniques are being adopted to reduce weight and increase performance. For instance, the integration of high-voltage wiring harnesses is becoming more prevalent, allowing for better energy management in electric vehicles. This shift is projected to contribute to a market growth rate of approximately 15% annually over the next five years. Furthermore, advancements in manufacturing processes, such as automated production lines, are streamlining the production of wiring harnesses, thereby reducing costs and improving quality. As these technologies evolve, they are likely to play a pivotal role in shaping the future of the Electric Vehicle Wiring Harness Market.