Government Regulations and Incentives

Government regulations and incentives play a crucial role in shaping the Electric Vehicle Plastic Market. Many governments are implementing stringent emissions standards and offering financial incentives for electric vehicle adoption. These policies encourage manufacturers to explore alternative materials, including advanced plastics, to comply with environmental regulations. For instance, the introduction of tax credits and subsidies for electric vehicle buyers has led to a significant increase in market penetration. As a result, the demand for lightweight and sustainable materials in vehicle production is expected to rise, further propelling the Electric Vehicle Plastic Market. This regulatory landscape not only fosters innovation but also aligns with global sustainability goals, creating a favorable environment for the growth of the industry.

Rising Demand for Lightweight Materials

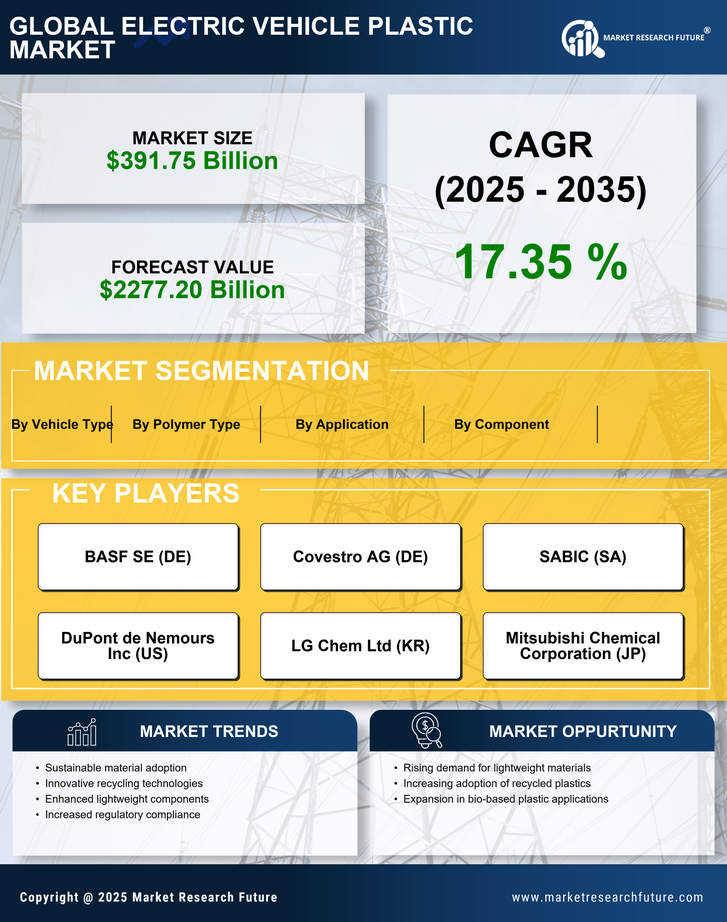

The Electric Vehicle Plastic Market is experiencing a notable surge in demand for lightweight materials. This trend is primarily driven by the automotive sector's need to enhance energy efficiency and extend the range of electric vehicles. Plastics, being significantly lighter than traditional materials like metals, contribute to weight reduction, which in turn improves vehicle performance. According to recent data, the use of advanced plastics in electric vehicles can reduce weight by up to 30%, leading to a potential increase in driving range by approximately 10 to 15%. As manufacturers strive to meet consumer expectations for longer-lasting battery life and improved efficiency, the Electric Vehicle Plastic Market is poised for substantial growth, reflecting a shift towards innovative material solutions.

Consumer Preference for Sustainable Products

Consumer preference for sustainable products is increasingly influencing the Electric Vehicle Plastic Market. As awareness of environmental issues grows, consumers are actively seeking vehicles that align with their values, including those made from recyclable and eco-friendly materials. This shift in consumer behavior is prompting manufacturers to prioritize sustainability in their production processes. The demand for plastics derived from renewable resources or those that can be easily recycled is on the rise. Market data suggests that vehicles incorporating sustainable materials can enhance brand loyalty and attract environmentally conscious buyers. Consequently, the Electric Vehicle Plastic Market is adapting to these preferences, leading to a greater emphasis on sustainable practices and materials in vehicle design and manufacturing.

Expansion of Electric Vehicle Infrastructure

The expansion of electric vehicle infrastructure is a pivotal driver for the Electric Vehicle Plastic Market. As charging stations and support facilities proliferate, the adoption of electric vehicles is expected to accelerate. This growth in infrastructure not only enhances consumer confidence but also stimulates demand for electric vehicles, subsequently increasing the need for innovative plastic components. The development of charging networks and maintenance facilities requires durable and lightweight materials, which are often sourced from the Electric Vehicle Plastic Market. Furthermore, projections indicate that the number of electric vehicles on the road could reach 30 million by 2030, creating a substantial market for plastics used in various vehicle applications. This infrastructure expansion is likely to catalyze further advancements in the industry, fostering a symbiotic relationship between electric vehicle adoption and plastic material innovation.

Technological Innovations in Material Science

Technological innovations in material science are transforming the Electric Vehicle Plastic Market. Advances in polymer chemistry and processing techniques have led to the development of high-performance plastics that offer enhanced durability, thermal stability, and resistance to environmental factors. These innovations enable manufacturers to produce components that meet the rigorous demands of electric vehicles, such as battery housings and structural parts. Recent studies indicate that the integration of new plastic composites can improve the lifespan of electric vehicle components by up to 20%. As the industry continues to evolve, the Electric Vehicle Plastic Market is likely to benefit from ongoing research and development efforts, which may yield even more efficient and sustainable material options.