Cost Efficiency

Cost efficiency remains a pivotal driver in the Digital 3D Printing Market. The technology enables manufacturers to produce complex geometries and customized products without the need for expensive tooling or molds. This capability significantly reduces production costs, particularly for low-volume and bespoke items. According to recent data, companies utilizing 3D printing can achieve cost savings of up to 70% in certain applications. Furthermore, the reduction in lead times associated with 3D printing allows businesses to respond more swiftly to market demands, enhancing their competitive edge. As industries increasingly recognize the financial benefits of adopting 3D printing technologies, the market is expected to expand, with more organizations integrating these solutions into their production processes.

Sustainability Initiatives

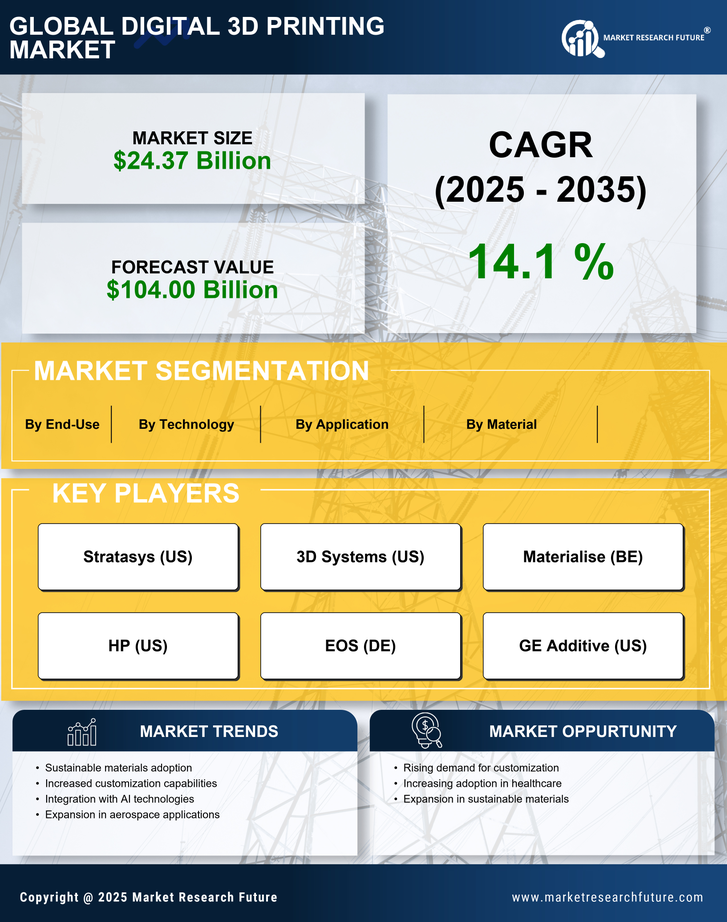

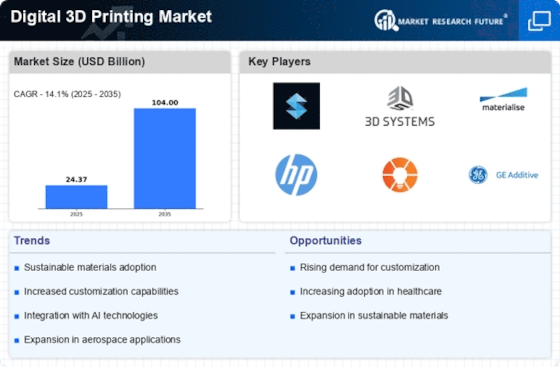

The Digital 3D Printing Market is increasingly influenced by sustainability initiatives. As environmental concerns rise, manufacturers are seeking ways to reduce waste and energy consumption. 3D printing technology allows for additive manufacturing, which minimizes material waste compared to traditional subtractive methods. This shift towards sustainable practices is evident, as the market is projected to grow at a compound annual growth rate of 23% from 2023 to 2030. Companies are investing in eco-friendly materials, such as biodegradable plastics and recycled composites, which further enhances the appeal of 3D printing. The emphasis on sustainability not only meets regulatory requirements but also aligns with consumer preferences for environmentally responsible products. Thus, the Digital 3D Printing Market is likely to see continued growth driven by these sustainability efforts.

Technological Advancements

Technological advancements are a crucial factor propelling the Digital 3D Printing Market forward. Innovations in printing technologies, such as multi-material printing and improved resolution, are enhancing the capabilities of 3D printers. These advancements enable the production of more intricate designs and functional prototypes, which are essential for industries like aerospace and healthcare. The market is witnessing a surge in the development of advanced materials, including metals and ceramics, which broadens the application scope of 3D printing. As of 2025, the market is projected to reach a valuation of approximately 45 billion USD, driven by these technological improvements. The continuous evolution of 3D printing technology suggests that the industry will remain dynamic, attracting investments and fostering new applications.

Increased Adoption in Healthcare

The Digital 3D Printing Market is experiencing increased adoption within the healthcare sector. Medical professionals are leveraging 3D printing for applications such as custom prosthetics, dental implants, and even bioprinting tissues. This trend is driven by the need for personalized medical solutions that cater to individual patient requirements. The market for 3D printed medical devices is expected to grow significantly, with estimates suggesting a CAGR of over 25% through 2030. The ability to create patient-specific models for surgical planning and training further underscores the value of 3D printing in healthcare. As the industry continues to embrace these innovations, the Digital 3D Printing Market is likely to expand, offering new opportunities for manufacturers and healthcare providers alike.

Growing Demand in Aerospace and Automotive

The Digital 3D Printing Market is witnessing a growing demand from the aerospace and automotive sectors. These industries are increasingly adopting 3D printing for producing lightweight components that enhance fuel efficiency and performance. The ability to manufacture complex parts with reduced weight is particularly advantageous in aerospace, where every gram counts. Recent studies indicate that the aerospace sector alone is projected to invest over 3 billion USD in 3D printing technologies by 2027. Additionally, automotive manufacturers are utilizing 3D printing for rapid prototyping and production of spare parts, which streamlines their supply chains. This trend suggests that the Digital 3D Printing Market will continue to thrive as these sectors seek innovative solutions to meet their evolving needs.