Sustainability Initiatives

Sustainability is becoming a pivotal driver in the Decoiler Machine Market, as manufacturers increasingly prioritize eco-friendly practices. The push for sustainable production methods is leading to the development of energy-efficient decoiler machines that minimize energy consumption and reduce carbon footprints. Recent studies indicate that companies adopting sustainable technologies can achieve energy savings of up to 30%. Furthermore, the emphasis on recycling and waste reduction is prompting manufacturers to invest in machines that facilitate the processing of recycled materials. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers. As sustainability becomes a core value for many businesses, the Decoiler Machine Market is likely to see a surge in demand for machines that support these initiatives, ultimately contributing to a more sustainable manufacturing landscape.

Increased Focus on Customization

Customization is emerging as a significant driver in the Decoiler Machine Market, as manufacturers strive to meet the unique needs of their clients. The demand for tailored solutions is growing, particularly in industries where specific material handling requirements exist. For instance, companies are increasingly seeking decoiler machines that can accommodate various coil sizes and materials, which necessitates a higher degree of flexibility in design and functionality. This trend is supported by market data indicating that customized machinery can lead to improved operational efficiency and reduced downtime. As businesses recognize the value of bespoke solutions, the Decoiler Machine Market is likely to see an uptick in demand for machines that offer customization options, thereby enhancing competitiveness and customer satisfaction.

Rising Demand from End-User Industries

The Decoiler Machine Market is significantly influenced by the rising demand from various end-user industries, including automotive, construction, and electronics. As these sectors expand, the need for efficient material handling solutions becomes increasingly critical. For example, the automotive industry, which is projected to grow at a compound annual growth rate of 4% over the next five years, relies heavily on decoiling machines for processing metal sheets and coils. Similarly, the construction sector's growth, driven by infrastructure development, is expected to boost the demand for decoiler machines. This trend indicates that as end-user industries evolve, the Decoiler Machine Market will likely experience sustained growth, driven by the need for advanced machinery that can meet the specific requirements of diverse applications.

Technological Advancements in Decoiler Machines

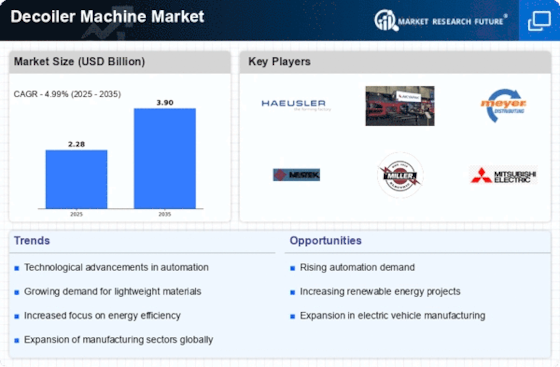

The Decoiler Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as automation and smart technology integration are enhancing the efficiency and precision of decoiling processes. For instance, the introduction of advanced sensors and control systems allows for real-time monitoring and adjustments, which can significantly reduce material waste. According to recent data, the adoption of automated decoiling systems is projected to increase by approximately 25% over the next five years. This trend not only improves operational efficiency but also aligns with the industry's shift towards Industry 4.0, where interconnected machines and data analytics play a crucial role. As manufacturers seek to optimize production lines, the demand for technologically advanced decoiler machines is likely to rise, driving growth in the Decoiler Machine Market.

Geographical Expansion of Manufacturing Facilities

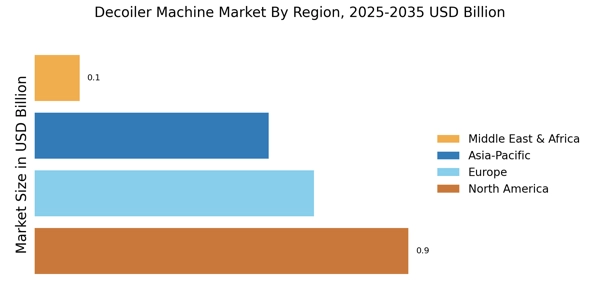

The geographical expansion of manufacturing facilities is a key driver in the Decoiler Machine Market. As companies seek to optimize production capabilities, there is a noticeable trend towards establishing manufacturing plants in emerging markets. This shift is often motivated by lower labor costs and access to new customer bases. For instance, regions in Asia and South America are witnessing an influx of manufacturing investments, which in turn increases the demand for decoiler machines. Additionally, the establishment of new facilities often necessitates the integration of modern decoiling technology to enhance productivity. Consequently, this geographical expansion is likely to propel the Decoiler Machine Market forward, as manufacturers invest in state-of-the-art equipment to support their operations in these new locations.