Growth in the Construction Industry

The construction industry is emerging as a vital driver for the Tungsten Carbide Powder Market, fueled by ongoing infrastructure development projects worldwide. Tungsten carbide is utilized in various construction applications, including cutting tools, wear parts, and concrete drilling equipment, owing to its durability and performance characteristics. As urbanization accelerates and governments invest in infrastructure, the demand for tungsten carbide products is expected to rise. Recent market analyses suggest that the construction sector could contribute significantly to the overall market growth, with estimates indicating a CAGR of approximately 4.5% in this segment. This growth reflects the increasing reliance on advanced materials to meet the challenges of modern construction.

Expanding Applications in Electronics

The Tungsten Carbide Powder Market is witnessing an expansion in applications within the electronics sector, driven by the need for high-performance materials in electronic components. Tungsten carbide is increasingly used in the production of semiconductor manufacturing tools, as well as in the fabrication of various electronic devices. The material's excellent thermal and electrical conductivity, combined with its mechanical strength, makes it suitable for a range of applications, including connectors and capacitors. Market forecasts indicate that the electronics segment is poised for growth, with an anticipated increase in demand for tungsten carbide products as technology advances. This trend highlights the versatility of tungsten carbide and its potential to meet the evolving needs of the electronics industry.

Rising Demand from the Oil and Gas Sector

The oil and gas sector is a significant driver for the Tungsten Carbide Powder Market, as the demand for durable and high-performance materials continues to rise. Tungsten carbide is extensively used in drilling applications, including drill bits and downhole tools, due to its exceptional hardness and resistance to wear. The increasing exploration and production activities in offshore and unconventional oil reserves are likely to boost the demand for tungsten carbide products. Market data indicates that the oil and gas industry accounts for a substantial share of the tungsten carbide market, with projections suggesting a growth rate of around 6% in this segment over the next few years. This trend underscores the critical role of tungsten carbide in enhancing operational efficiency and reducing downtime in drilling operations.

Increased Focus on Wear-Resistant Materials

The growing emphasis on wear-resistant materials is a significant driver for the Tungsten Carbide Powder Market. Industries such as mining, manufacturing, and automotive are increasingly seeking materials that can withstand harsh operating conditions and extend the lifespan of tools and components. Tungsten carbide, known for its exceptional hardness and wear resistance, is becoming the material of choice for various applications, including cutting tools and industrial machinery. Recent Industry expert's suggest that the demand for wear-resistant materials is expected to grow at a rate of approximately 5.5% annually, reflecting the industry's shift towards more durable solutions. This trend underscores the importance of tungsten carbide in enhancing productivity and reducing maintenance costs across multiple sectors.

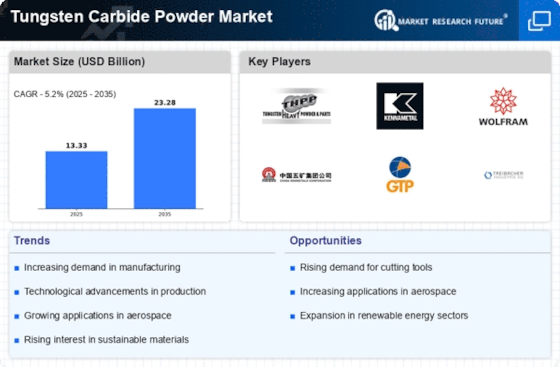

Technological Advancements in Manufacturing

The Tungsten Carbide Powder Market is experiencing a notable transformation due to advancements in manufacturing technologies. Innovations such as additive manufacturing and precision milling are enhancing the production processes of tungsten carbide powders. These technologies allow for the creation of more complex geometries and improved material properties, which are essential for various applications, including cutting tools and wear-resistant components. As a result, the market is projected to witness a compound annual growth rate (CAGR) of approximately 5% over the next few years. This growth is driven by the increasing need for high-performance materials in industries such as aerospace, automotive, and mining, where tungsten carbide's superior hardness and wear resistance are highly valued.