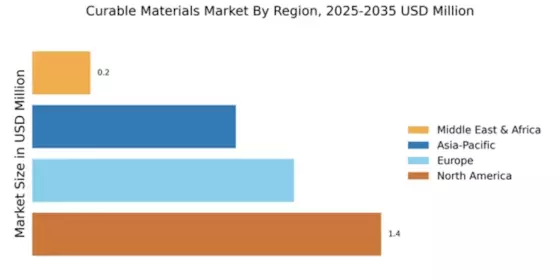

Market Growth Projections

The Global Curable Materials Market Industry is projected to experience substantial growth over the next decade. With a market value of 235.94 USD Billion in 2024, it is expected to reach 541.32 USD Billion by 2035. This growth trajectory indicates a robust CAGR of 7.84% from 2025 to 2035, reflecting the increasing adoption of curable materials across various industries. The expansion is driven by technological advancements, regulatory support, and rising consumer demand for sustainable solutions. As the market evolves, stakeholders are likely to explore new opportunities and innovations to capitalize on this growth.

Expansion of End-User Industries

The Global Curable Materials Market Industry is experiencing growth due to the expansion of key end-user industries, including automotive, construction, and electronics. These sectors are increasingly utilizing curable materials for their superior properties, such as durability and resistance to environmental factors. For example, the automotive industry employs curable coatings to enhance vehicle aesthetics and longevity. As these industries continue to expand globally, the demand for curable materials is expected to rise, contributing to a market valuation of 541.32 USD Billion by 2035. This growth reflects the increasing reliance on advanced materials across diverse applications.

Rising Demand for Eco-Friendly Solutions

The Global Curable Materials Market Industry is witnessing a notable shift towards sustainable and eco-friendly materials. As environmental regulations tighten and consumer preferences evolve, manufacturers are increasingly adopting curable materials that minimize environmental impact. For instance, bio-based resins and low-VOC coatings are gaining traction, driven by their reduced carbon footprint. This trend is expected to propel the market's growth, with projections indicating a market value of 235.94 USD Billion in 2024. Companies that prioritize sustainability are likely to capture a larger share of the market, as eco-conscious consumers become more prevalent.

Regulatory Support for Advanced Materials

Government regulations promoting the use of advanced materials are playing a crucial role in shaping the Global Curable Materials Market Industry. Policies aimed at reducing hazardous substances and promoting sustainable practices encourage manufacturers to adopt curable materials that comply with safety standards. This regulatory support not only fosters innovation but also enhances market competitiveness. As governments worldwide implement stricter environmental regulations, the demand for compliant curable materials is likely to surge. Consequently, this trend is expected to bolster market growth, aligning with the increasing focus on sustainability and safety in material applications.

Growing Consumer Awareness and Preferences

Consumer awareness regarding the benefits of curable materials is driving growth in the Global Curable Materials Market Industry. As consumers become more informed about the advantages of using high-performance materials, such as enhanced durability and lower maintenance costs, their preferences are shifting towards products that incorporate these materials. This shift is particularly evident in sectors like construction and consumer goods, where quality and longevity are paramount. Manufacturers that respond to these changing consumer preferences by offering innovative curable materials are likely to gain a competitive edge in the market, further propelling its expansion.

Technological Advancements in Material Science

Innovations in material science are significantly influencing the Global Curable Materials Market Industry. The development of advanced curing technologies, such as UV and electron beam curing, enhances the performance and efficiency of curable materials. These technologies allow for faster curing times and improved product quality, which are essential for various applications, including coatings and adhesives. As a result, manufacturers are increasingly investing in research and development to leverage these advancements. This focus on technology is anticipated to contribute to the market's growth, with a projected CAGR of 7.84% from 2025 to 2035.