Emergence of Industry 4.0

The emergence of Industry 4.0 is reshaping the Coordinate Measuring Machine Market. As industries adopt smart manufacturing practices, the integration of CMMs with IoT and data analytics is becoming increasingly prevalent. This shift allows for real-time monitoring and data collection, enhancing the decision-making process and operational efficiency. By 2025, it is projected that the market for CMMs integrated with Industry 4.0 technologies will grow significantly, potentially accounting for over 30% of total CMM sales. This trend indicates a move towards more interconnected and automated measurement systems, which can provide manufacturers with valuable insights into their production processes. The adoption of Industry 4.0 principles is likely to drive innovation and competitiveness within the CMM market.

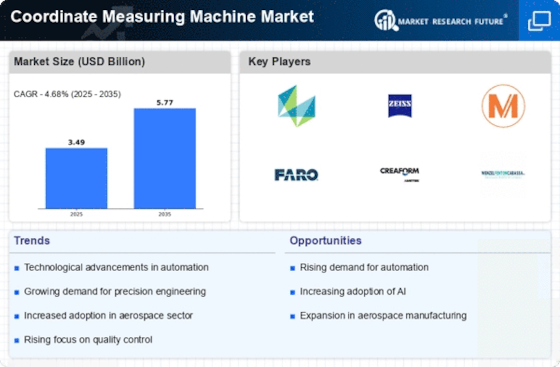

Technological Advancements in CMM

Technological advancements are significantly influencing the Coordinate Measuring Machine Market. Innovations such as laser scanning, optical measurement, and advanced software integration are enhancing the capabilities of CMMs. These technologies allow for faster and more accurate measurements, which are crucial in high-stakes industries like aerospace and automotive. The introduction of portable CMMs has also expanded the application range, enabling on-site measurements that were previously challenging. As of 2025, it is estimated that the market for technologically advanced CMMs will account for over 40% of total sales, indicating a shift towards more sophisticated measurement solutions. This trend suggests that companies are increasingly recognizing the value of investing in cutting-edge measurement technologies.

Growth of the Manufacturing Sector

The growth of the manufacturing sector is a pivotal driver for the Coordinate Measuring Machine Market. As manufacturing processes become more complex, the need for precise measurement tools has escalated. In 2025, the manufacturing sector is expected to contribute significantly to the CMM market, with projections indicating a market share of approximately 55%. This growth is attributed to the increasing automation and digitization of manufacturing processes, which necessitate the use of advanced measurement systems to ensure product quality and compliance. Furthermore, the expansion of industries such as electronics and medical devices is likely to further bolster the demand for coordinate measuring machines, as these sectors require high precision and reliability in their production processes.

Increasing Focus on Quality Assurance

An increasing focus on quality assurance is driving the Coordinate Measuring Machine Market. As companies strive to enhance their product quality and reduce defects, the implementation of CMMs has become a strategic priority. In 2025, it is anticipated that the quality assurance segment will represent a substantial portion of the CMM market, with an estimated growth rate of 7% annually. This trend is particularly evident in industries such as automotive and aerospace, where the cost of defects can be prohibitively high. By integrating CMMs into their quality control processes, manufacturers can achieve greater accuracy and consistency, thereby improving overall operational efficiency. This emphasis on quality assurance is likely to continue shaping the market landscape in the coming years.

Rising Demand for Precision Engineering

The Coordinate Measuring Machine Market is experiencing a notable surge in demand for precision engineering across various sectors, including aerospace, automotive, and manufacturing. As industries increasingly prioritize quality control and accuracy, the adoption of coordinate measuring machines has become essential. In 2025, the market is projected to reach a valuation of approximately USD 2.5 billion, reflecting a compound annual growth rate of around 6.5% from previous years. This growth is driven by the need for enhanced measurement capabilities and the ability to meet stringent regulatory standards. Companies are investing in advanced CMM technologies to ensure that their products meet the highest quality benchmarks, thereby fostering a competitive edge in the market.