North America : Market Leader in Repair Services

North America is poised to maintain its leadership in the Conveyor Systems Repair Services Market, holding a significant market share of 75% in 2024. The region's growth is driven by a robust manufacturing sector, increasing automation, and stringent safety regulations that necessitate regular maintenance and repair services. The demand for advanced technologies and efficient supply chain solutions further propels market expansion, supported by government initiatives promoting industrial innovation.

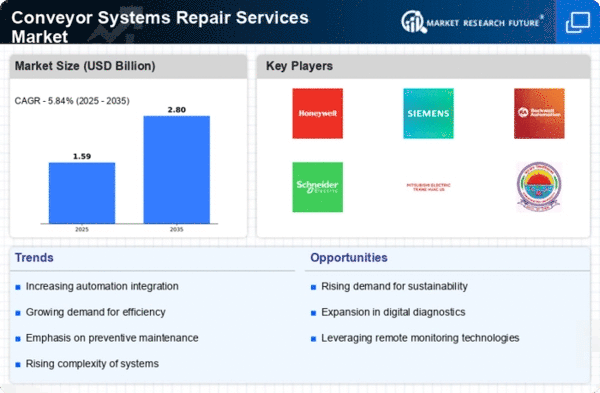

The competitive landscape in North America is characterized by the presence of major players such as Honeywell, Rockwell Automation, and Emerson Electric. These companies leverage cutting-edge technologies to enhance service offerings and improve operational efficiency. The U.S. stands out as the leading country, with a strong focus on automation and smart manufacturing, ensuring a steady demand for conveyor repair services. The market is expected to grow as industries increasingly prioritize maintenance to minimize downtime and enhance productivity.

Europe : Emerging Market with Growth Potential

Europe's Conveyor Systems Repair Services Market is projected to grow, capturing a market share of 40% by 2025. The region benefits from a strong industrial base, particularly in Germany and France, where manufacturing and logistics sectors are expanding. Regulatory frameworks emphasizing safety and efficiency are driving demand for repair services, as companies seek to comply with stringent EU regulations. Additionally, the push for sustainability is leading to increased investments in maintenance and repair to extend equipment life.

Germany is the leading country in this market, with significant contributions from companies like Siemens and KUKA. The competitive landscape is marked by a mix of established players and emerging firms focusing on innovative repair solutions. The presence of advanced manufacturing technologies and a skilled workforce further enhances the region's capabilities. As industries adapt to changing market dynamics, the demand for reliable conveyor repair services is expected to rise, fostering growth in the sector.

Asia-Pacific : Rapidly Growing Market Segment

The Asia-Pacific region is witnessing significant growth in the Conveyor Systems Repair Services Market, with a projected market share of 25% by 2025. This growth is fueled by rapid industrialization, increasing manufacturing activities, and a rising focus on automation across countries like China, Japan, and India. Government initiatives aimed at enhancing infrastructure and promoting manufacturing are also contributing to the demand for repair services, as companies seek to optimize their operations and reduce downtime.

China leads the region in terms of market size and growth potential, with major players like Mitsubishi Electric and FANUC driving innovation in repair services. The competitive landscape is evolving, with both local and international companies vying for market share. As industries continue to modernize and adopt advanced technologies, the need for efficient and reliable conveyor repair services is expected to grow, positioning Asia-Pacific as a key player in the global market.

Middle East and Africa : Emerging Market with Challenges

The Middle East and Africa region is gradually emerging in the Conveyor Systems Repair Services Market, holding a market share of 10% by 2025. The growth is primarily driven by increasing investments in infrastructure and manufacturing, particularly in countries like the UAE and South Africa. However, challenges such as economic fluctuations and regulatory hurdles may impact market growth. Despite these challenges, the demand for repair services is expected to rise as industries focus on maintaining operational efficiency and minimizing downtime.

The competitive landscape in this region is still developing, with a mix of local and international players. Companies are beginning to recognize the importance of reliable repair services to support their operations. As the region continues to invest in industrial growth, the demand for conveyor repair services is likely to increase, presenting opportunities for both established and emerging players in the market.