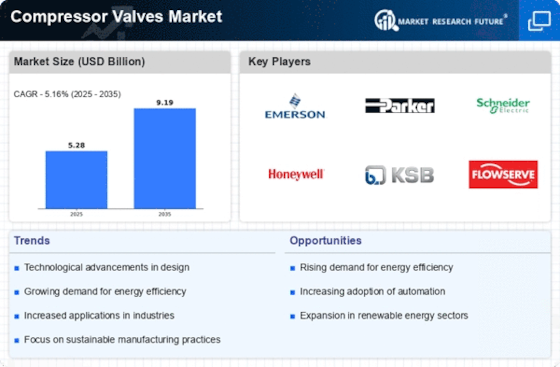

Growth in Renewable Energy Sector

The Compressor Valves Market is poised for growth due to the increasing investments in the renewable energy sector. As countries transition towards sustainable energy sources, the demand for compressed air and gas systems in renewable energy applications, such as wind and solar power, is on the rise. Compressor valves are essential components in these systems, facilitating the efficient operation of energy generation and storage solutions. The renewable energy sector is projected to grow at a CAGR of 8%, creating substantial opportunities for compressor valve manufacturers. This growth is likely to drive innovation in valve technology, as companies seek to develop products that meet the specific requirements of renewable energy applications. The alignment of the Compressor Valves Market with the renewable energy trend not only supports environmental goals but also enhances the market's long-term viability.

Rising Demand for Energy Efficiency

The Compressor Valves Market is experiencing a notable increase in demand for energy-efficient solutions. As industries strive to reduce operational costs and minimize environmental impact, the focus on energy efficiency has intensified. Compressor valves play a crucial role in optimizing the performance of compressors, thereby enhancing energy savings. According to recent data, energy-efficient compressor systems can reduce energy consumption by up to 30%. This trend is particularly evident in sectors such as manufacturing and HVAC, where energy costs constitute a significant portion of operational expenses. Consequently, manufacturers of compressor valves are innovating to meet this demand, leading to advancements in valve design and materials that improve efficiency. The growing emphasis on energy conservation is likely to propel the Compressor Valves Market forward, as companies seek to adopt technologies that align with sustainability goals.

Expansion of Industrial Applications

The Compressor Valves Market is witnessing an expansion in industrial applications, driven by the increasing need for compressed air and gas in various sectors. Industries such as oil and gas, chemical processing, and food and beverage are increasingly relying on compressor systems for their operations. This reliance necessitates the use of high-quality compressor valves to ensure reliability and efficiency. For instance, the oil and gas sector, which is projected to grow at a CAGR of 4.5%, heavily depends on compressor valves for gas compression and transportation. As these industries expand, the demand for specialized compressor valves tailored to specific applications is likely to rise. This trend not only enhances the market potential for compressor valves but also encourages innovation in valve technology, thereby contributing to the overall growth of the Compressor Valves Market.

Technological Innovations in Valve Design

The Compressor Valves Market is benefiting from ongoing technological innovations in valve design and manufacturing processes. Advances in materials science and engineering have led to the development of more durable and efficient compressor valves. Innovations such as smart valves equipped with sensors and IoT capabilities are emerging, allowing for real-time monitoring and optimization of compressor performance. This technological evolution is particularly relevant in sectors where precision and reliability are paramount, such as aerospace and automotive. The integration of smart technologies is expected to enhance operational efficiency and reduce maintenance costs, thereby attracting more investments into the Compressor Valves Market. As manufacturers continue to explore new technologies, the market is likely to see a proliferation of advanced valve solutions that cater to the evolving needs of various industries.

Regulatory Compliance and Safety Standards

The Compressor Valves Market is significantly influenced by regulatory compliance and safety standards that govern industrial operations. Governments and regulatory bodies are increasingly implementing stringent regulations to ensure safety and environmental protection in various industries. These regulations often mandate the use of high-performance compressor valves that can withstand extreme conditions and prevent leaks. For example, the introduction of new safety standards in the chemical processing industry has led to a surge in demand for valves that meet these requirements. Companies are compelled to invest in advanced compressor valve technologies to comply with these regulations, which in turn drives market growth. The emphasis on safety and compliance not only enhances the reliability of compressor systems but also fosters innovation within the Compressor Valves Market, as manufacturers strive to develop products that meet evolving standards.