Growth in Automotive Applications

The automotive industry is undergoing a transformation, with a growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions. This shift is propelling the Composite Tooling Market forward, as manufacturers seek innovative tooling solutions to produce composite components. In 2025, the automotive sector is expected to represent around 25% of the composite tooling market. The integration of composites in vehicle design not only enhances performance but also aligns with regulatory pressures for sustainability. As electric and hybrid vehicles gain traction, the demand for advanced composite tooling is likely to escalate, presenting opportunities for companies to innovate and expand their offerings.

Rising Demand in Aerospace Sector

The aerospace sector is experiencing a notable surge in demand for composite materials, which is significantly influencing the Composite Tooling Market. As aircraft manufacturers increasingly adopt lightweight materials to enhance fuel efficiency and performance, the need for advanced composite tooling solutions becomes paramount. In 2025, the aerospace industry is projected to account for approximately 30% of the total composite tooling market. This trend is driven by the ongoing development of next-generation aircraft, which require sophisticated tooling to produce complex composite structures. Consequently, companies specializing in composite tooling are likely to see increased orders and investments, as they strive to meet the evolving needs of aerospace manufacturers.

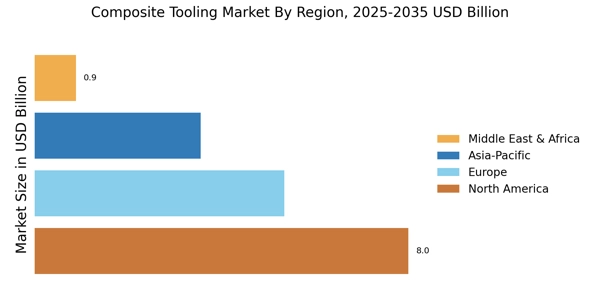

Emerging Markets and Global Expansion

Emerging markets are playing a crucial role in the expansion of the Composite Tooling Market. Countries in Asia and South America are witnessing rapid industrialization and infrastructure development, leading to increased demand for composite materials in various applications. In 2025, it is estimated that these regions will contribute significantly to the overall market growth, with a projected increase of 20% in composite tooling demand. As local manufacturers seek to enhance their production capabilities, the need for advanced tooling solutions becomes evident. This trend presents opportunities for established companies to enter new markets and collaborate with local players, thereby fostering innovation and growth in the composite tooling sector.

Increased Investment in Renewable Energy

The renewable energy sector, particularly wind energy, is becoming a significant driver for the Composite Tooling Market. The production of wind turbine blades, which often utilize composite materials for their lightweight and durable properties, is expanding rapidly. In 2025, the wind energy market is projected to require a substantial increase in composite tooling solutions, as manufacturers ramp up production to meet growing energy demands. This trend is likely to result in increased investments in tooling technologies that can efficiently produce large-scale composite components. As the world shifts towards sustainable energy sources, the composite tooling market is poised for growth driven by this sector.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are reshaping the Composite Tooling Market. Innovations such as automated fiber placement and 3D printing are streamlining production, reducing lead times, and enhancing precision in tooling applications. These technologies enable manufacturers to create complex geometries and optimize material usage, which is increasingly important in competitive markets. In 2025, it is anticipated that the adoption of these technologies will lead to a 15% increase in efficiency for composite tooling production. As companies invest in state-of-the-art manufacturing techniques, they are likely to gain a competitive edge, further driving growth in the composite tooling sector.