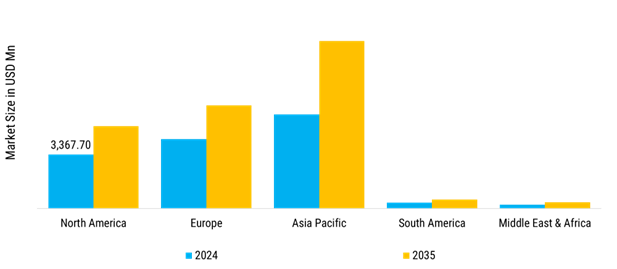

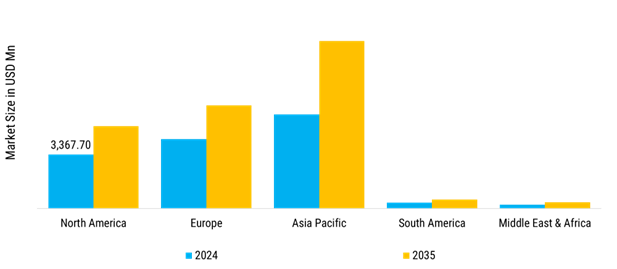

Asia-Pacific: Manufacturing Powerhouse

Asia-Pacific is the largest market for Commercial Heat Treating services, holding approximately 40% of the global market share. The region's growth is driven by massive manufacturing output, infrastructure development, and automotive industry expansion. The presence of major manufacturing hubs and a robust industrial ecosystem further fuel demand for heat treating services. Leading countries in this region include China, India, and Japan, where companies like local heat treaters and international players are making substantial impacts. The region is characterized by high production volumes and cost-competitive manufacturing, with significant contributions from automotive, electronics, and heavy machinery sectors. China leads the market, followed by India and Japan, with substantial demand from key industrial clusters. The competitive landscape is characterized by rapid capacity expansion and a focus on automation and process efficiency. Companies are increasingly investing in advanced furnace technology and quality systems to meet growing demand for high-performance heat treated components.

North America: Technology and Innovation Leader

North America represents a significant market for Commercial Heat Treating services, accounting for approximately 30% of the global market share. The region's growth is driven by advanced manufacturing capabilities, aerospace industry concentration, and stringent quality requirements. The presence of major automotive and aerospace OEMs and a strong focus on technology adoption enhance demand for specialized heat treating services. The United States leads the market, followed by Canada and Mexico, with significant contributions from key players like Bodycote, Bluewater Thermal Solutions, and Paulo. The competitive landscape is characterized by technological innovation and emphasis on precision heat treating capabilities. Companies are increasingly investing in advanced vacuum furnaces, atmosphere control systems, and quality certification to meet the demanding requirements of aerospace, automotive, and tooling industries, positioning North America as a hub for high-value heat treating services.

Europe: Quality and Precision Market

Europe is witnessing steady growth in the Commercial Heat Treating market, accounting for approximately 25% of the global share. The region's growth is propelled by strong automotive manufacturing presence, aerospace industry requirements, and emphasis on quality standards and environmental compliance. The automotive and machine tool industries drive significant demand for heat treating services. Leading countries in this region include Germany, France, and the United Kingdom, where companies like Aichelin Group and other specialized heat treaters are making substantial impacts. The competitive landscape is evolving with a focus on energy efficiency, environmental sustainability, and advanced process control. The emphasis on Industry 4.0 integration and carbon neutrality is shaping market dynamics as organizations seek efficient and environmentally responsible heat treating solutions.

Middle East and Africa: Emerging Industrial Market

The Middle East and Africa region is gradually emerging in the Commercial Heat Treating market, currently holding about 5% of the global share. The growth is driven by increasing investments in manufacturing infrastructure, oil and gas industry requirements, and rising demand for heat treating services among industrial enterprises. Governments in the region are actively promoting industrial development, which is expected to further boost market growth in the coming years. Leading countries include the UAE, Saudi Arabia, and South Africa, where local and international heat treating service providers are beginning to establish operations. The competitive landscape is still developing, with a mix of regional and international companies entering the market. As businesses increasingly recognize the benefits of professional heat treating services for component reliability and performance, the region is poised for significant growth driven by industrialization and infrastructure development initiatives.