North America : Market Leader in Cold Storage

North America is poised to maintain its leadership in the Cold Storage Equipment Maintenance and Repair Market, holding a significant market share of 3.2 in 2024. The region's growth is driven by increasing demand for efficient cold chain logistics, stringent food safety regulations, and advancements in refrigeration technology. The rising e-commerce sector further fuels the need for reliable cold storage solutions, ensuring product integrity during transportation.

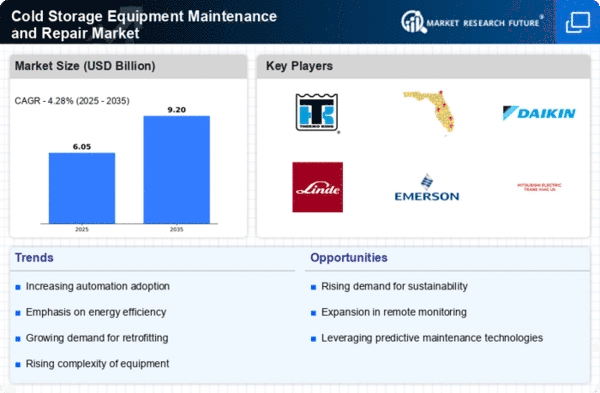

The competitive landscape in North America is robust, featuring key players such as Thermo King, Carrier Transicold, and Emerson Electric. These companies are investing heavily in innovative technologies and service offerings to enhance operational efficiency. The U.S. stands out as the leading country, supported by a well-established infrastructure and a growing focus on sustainability in cold storage practices. This dynamic environment positions North America as a critical hub for cold storage solutions.

Europe : Emerging Cold Storage Hub

Europe is witnessing a significant transformation in the Cold Storage Equipment Maintenance and Repair Market, with a market size of 1.8 in 2024. The growth is propelled by increasing consumer demand for fresh and frozen foods, alongside stringent EU regulations on food safety and quality. The region's commitment to sustainability and energy efficiency in cold storage practices is also a key driver, encouraging investments in modern technologies and infrastructure.

Leading countries in Europe include Germany, France, and the UK, where major players like Linde Material Handling and GEA Group are actively enhancing their service capabilities. The competitive landscape is characterized by a mix of established firms and emerging startups focusing on innovative solutions. As the market evolves, collaboration between technology providers and logistics companies is expected to strengthen the cold storage ecosystem in Europe.

Asia-Pacific : Rapidly Growing Market

Asia-Pacific is emerging as a rapidly growing market for Cold Storage Equipment Maintenance and Repair, with a market size of 0.9 in 2024. The region's growth is fueled by rising urbanization, increasing disposable incomes, and a growing demand for perishable goods. Additionally, government initiatives aimed at enhancing food safety and reducing waste are driving investments in cold storage infrastructure, making it a priority for many countries in the region.

Key players in Asia-Pacific include Daikin Industries and Mitsubishi Electric, who are focusing on expanding their service networks and product offerings. Countries like China and India are leading the charge, with significant investments in cold chain logistics. The competitive landscape is becoming increasingly dynamic, with both local and international players vying for market share, indicating a promising future for cold storage solutions in the region.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region is recognized for its emerging potential in the Cold Storage Equipment Maintenance and Repair Market, with a market size of 0.9 in 2024. The growth is driven by increasing investments in food processing and distribution, alongside a rising demand for temperature-sensitive products. Additionally, government initiatives aimed at improving food security and reducing post-harvest losses are catalyzing the development of cold storage facilities across the region.

Leading countries such as South Africa and the UAE are at the forefront of this growth, with key players like Johnson Controls and Bitzer expanding their operations. The competitive landscape is characterized by a mix of established firms and new entrants, focusing on innovative solutions tailored to local market needs. As the region continues to develop, the cold storage sector is expected to play a crucial role in enhancing food supply chains.