Rising Labor Costs

In the current economic landscape, rising labor costs are compelling organizations to invest in automation solutions, thereby propelling the Cohesive Automated Equipment Market. As wages continue to increase across various sectors, companies are seeking ways to maintain profitability while ensuring operational efficiency. Automated equipment offers a viable solution by reducing the dependency on manual labor and minimizing human error. Market data suggests that businesses that implement cohesive automated systems can achieve up to a 30% reduction in labor costs, making it an attractive proposition. This trend is likely to accelerate the adoption of cohesive automated solutions, as firms aim to streamline their operations and enhance productivity in a cost-effective manner.

Regulatory Compliance

The increasing complexity of regulatory requirements across various industries is influencing the Cohesive Automated Equipment Market. Companies are required to adhere to stringent safety, environmental, and quality standards, which necessitates the implementation of automated systems that can ensure compliance. Automated equipment can facilitate accurate reporting and monitoring, thereby reducing the risk of non-compliance penalties. Market analysis indicates that organizations investing in cohesive automated solutions are better positioned to navigate regulatory challenges, with a 20% decrease in compliance-related issues reported. This trend suggests that the need for regulatory adherence will continue to drive the demand for cohesive automated equipment in the foreseeable future.

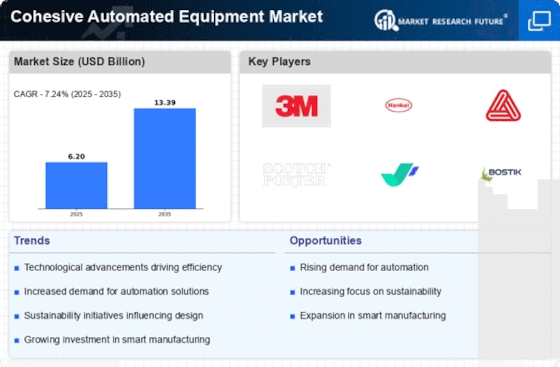

Technological Advancements

The Cohesive Automated Equipment Market is experiencing a surge in technological advancements that enhance operational efficiency and productivity. Innovations such as artificial intelligence, machine learning, and the Internet of Things are being integrated into automated equipment, allowing for real-time data analysis and improved decision-making processes. This trend is likely to drive the market as companies seek to optimize their production lines and reduce operational costs. According to recent data, the adoption of advanced automation technologies is projected to increase by 25% over the next five years, indicating a robust growth trajectory for the Cohesive Automated Equipment Market. As businesses strive for competitive advantage, the demand for sophisticated automated solutions is expected to rise significantly.

Focus on Operational Efficiency

The relentless pursuit of operational efficiency is a primary driver of the Cohesive Automated Equipment Market. Organizations are increasingly recognizing the importance of optimizing their processes to enhance productivity and reduce waste. Automated equipment provides the tools necessary to streamline operations, minimize downtime, and improve overall efficiency. Data indicates that companies implementing cohesive automated solutions can achieve up to a 50% increase in operational efficiency. This focus on efficiency is likely to propel further investments in automation technologies, as businesses strive to remain competitive in an ever-evolving market landscape.

Increased Demand for Quality and Consistency

The demand for high-quality products and consistent output is driving the Cohesive Automated Equipment Market. As consumer expectations evolve, manufacturers are under pressure to deliver products that meet stringent quality standards. Automated equipment plays a crucial role in ensuring uniformity and precision in production processes, which is essential for maintaining brand reputation and customer satisfaction. Recent studies indicate that companies utilizing cohesive automated systems report a 40% improvement in product quality and consistency. This growing emphasis on quality is likely to fuel investments in automated solutions, as businesses recognize the importance of meeting consumer demands while minimizing production variances.