Expansion of the Construction Sector

The Clinching Machine Market is benefiting from the expansion of the construction sector, particularly in the development of prefabricated structures. As the construction industry embraces innovative building techniques, the need for efficient joining methods becomes paramount. Clinching machines offer a viable solution for assembling prefabricated components, ensuring structural integrity while minimizing labor costs. The construction sector is projected to grow at a compound annual growth rate of around 5%, driven by urbanization and infrastructure development. This growth presents a significant opportunity for the Clinching Machine Market, as manufacturers seek to adopt advanced joining technologies to meet the demands of modern construction practices.

Growth in Electric Vehicle Production

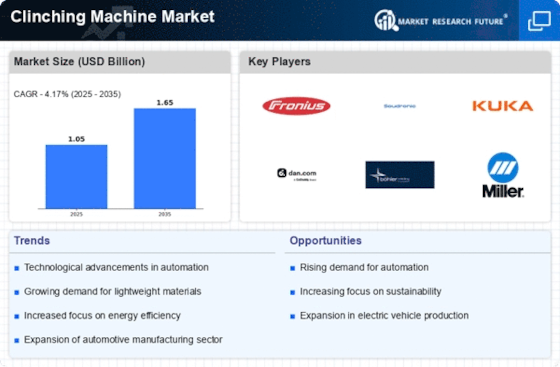

The Clinching Machine Market is poised for growth due to the surge in electric vehicle (EV) production. As automakers pivot towards electric mobility, the demand for efficient manufacturing processes intensifies. Clinching machines play a crucial role in the assembly of EV components, offering reliable and robust joining methods that are essential for battery enclosures and lightweight structures. Reports indicate that the EV market is expected to expand at a compound annual growth rate of approximately 20% over the next decade. This rapid growth in EV production creates a favorable environment for the Clinching Machine Market, as manufacturers increasingly adopt advanced joining technologies to meet the evolving demands of the automotive sector.

Rising Demand for Lightweight Materials

The Clinching Machine Market experiences a notable increase in demand for lightweight materials, particularly in the automotive and aerospace sectors. As manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of materials such as aluminum and advanced composites becomes essential. This shift necessitates the use of clinching machines, which provide effective joining solutions without compromising the integrity of these materials. The market for lightweight materials is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. Consequently, the Clinching Machine Market is likely to benefit from this trend, as manufacturers seek innovative joining techniques that align with their sustainability goals.

Increased Focus on Automation and Industry 4.0

The Clinching Machine Market is significantly influenced by the ongoing trend towards automation and the principles of Industry 4.0. As manufacturers seek to enhance productivity and reduce operational costs, the integration of automated clinching machines becomes increasingly attractive. These machines not only improve efficiency but also ensure consistent quality in production processes. The market for automation in manufacturing is projected to grow substantially, with estimates indicating a potential increase of over 15% annually. This trend suggests that the Clinching Machine Market will likely see a rise in demand for automated solutions, as companies strive to remain competitive in an increasingly digital landscape.

Rising Investment in Renewable Energy Infrastructure

The Clinching Machine Market is likely to experience growth due to the increasing investment in renewable energy infrastructure. As countries prioritize sustainable energy sources, the demand for wind turbines, solar panels, and other renewable technologies rises. Clinching machines are essential in the assembly of these components, providing strong and reliable joints that are critical for performance and durability. The renewable energy sector is expected to grow at a compound annual growth rate of approximately 8% over the next several years. This trend indicates that the Clinching Machine Market will benefit from the heightened focus on renewable energy, as manufacturers seek efficient joining solutions to support the expansion of this vital sector.