North America : Market Leader in MRO Services

North America is poised to maintain its leadership in the Chemical Reactor Maintenance and MRO Services Market, holding a market size of $5.0 billion. Key growth drivers include stringent regulatory frameworks, increasing investments in infrastructure, and a rising focus on safety and efficiency in chemical processing. The demand for advanced maintenance solutions is further fueled by the need for compliance with environmental regulations and operational excellence.

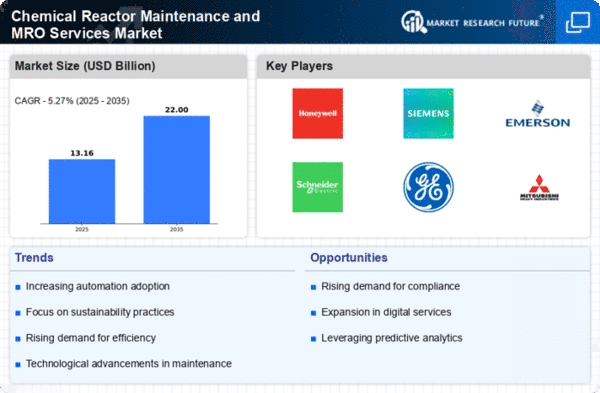

The competitive landscape in North America is robust, featuring major players such as Honeywell, Emerson Electric, and General Electric. These companies leverage innovative technologies and strategic partnerships to enhance service offerings. The U.S. stands out as the leading country, supported by a well-established industrial base and significant R&D investments. This region's market dynamics are characterized by a strong emphasis on sustainability and digital transformation in maintenance practices.

Europe : Emerging Market with Growth Potential

Europe's Chemical Reactor Maintenance and MRO Services Market is valued at $3.5 billion, driven by increasing regulatory support and a shift towards sustainable practices. The European Union's stringent environmental regulations are catalyzing investments in maintenance services, ensuring compliance and enhancing operational efficiency. The growing emphasis on safety standards and technological advancements further propels market growth, making it a key player in the global landscape.

Leading countries in this region include Germany, France, and the UK, where major companies like Siemens and Schneider Electric are actively expanding their service portfolios. The competitive environment is marked by innovation and collaboration among industry players, focusing on digital solutions and predictive maintenance. This strategic approach positions Europe as a significant contributor to The Chemical Reactor Maintenance and MRO Services, with a strong emphasis on sustainability and efficiency.

Asia-Pacific : Rapidly Growing MRO Sector

The Asia-Pacific region, with a market size of $3.0 billion, is rapidly emerging as a powerhouse in the Chemical Reactor Maintenance and MRO Services Market. Key growth drivers include industrialization, urbanization, and increasing investments in chemical manufacturing. Countries like China and India are witnessing a surge in demand for maintenance services, driven by the need for operational efficiency and compliance with evolving regulations. The region's focus on technological advancements is also a significant catalyst for growth.

China leads the market in Asia-Pacific, supported by its vast industrial base and government initiatives promoting modernization. Major players such as Mitsubishi Heavy Industries and KBR are expanding their presence, leveraging local partnerships to enhance service delivery. The competitive landscape is characterized by a mix of global and regional players, all vying to capture the growing demand for MRO services in this dynamic market.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, with a market size of $1.0 billion, presents significant growth opportunities in the Chemical Reactor Maintenance and MRO Services Market. The region is witnessing increased investments in infrastructure and industrial development, driven by government initiatives aimed at diversifying economies. The demand for maintenance services is expected to rise as industries focus on enhancing operational efficiency and adhering to safety regulations.

Leading countries in this region include the UAE and South Africa, where key players are beginning to establish a foothold. Companies like Fluor Corporation and Jacobs Engineering are exploring partnerships to tap into the growing market. The competitive landscape is evolving, with a focus on localized service delivery and innovative solutions to meet the unique challenges of the region, positioning it for future growth.