Growth in Renewable Energy Sector

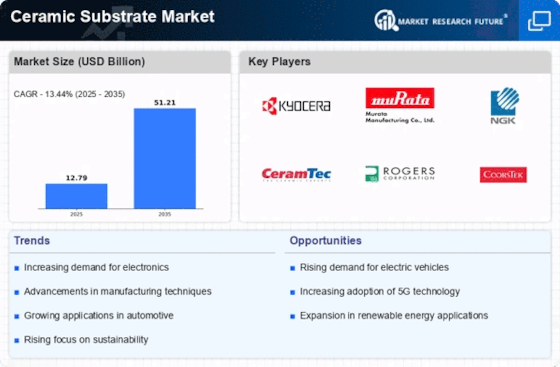

The expansion of the renewable energy sector serves as a significant driver for the Ceramic Substrate Market. With a global emphasis on sustainable energy solutions, ceramic substrates are increasingly utilized in solar inverters and wind turbine applications. These substrates offer durability and thermal stability, which are essential for the efficient operation of renewable energy systems. The renewable energy market is projected to grow at a CAGR of approximately 8% over the next decade, indicating a rising demand for components that enhance energy conversion efficiency. As such, the Ceramic Substrate Market is poised to benefit from this trend, as manufacturers adapt to the growing needs of the renewable energy landscape.

Increased Focus on Miniaturization

The trend towards miniaturization in electronic devices is a crucial driver for the Ceramic Substrate Market. As consumer electronics evolve, there is a growing demand for smaller, more efficient components that do not compromise on performance. Ceramic substrates are ideal for this purpose, as they provide high thermal conductivity and electrical insulation in compact designs. The consumer electronics market is anticipated to reach over 1 trillion USD by 2025, which suggests a substantial increase in the need for advanced materials. This trend towards miniaturization is likely to propel the Ceramic Substrate Market, as manufacturers seek innovative solutions to meet the demands of modern electronics.

Rising Demand for Electric Vehicles

The increasing demand for electric vehicles (EVs) is a pivotal driver for the Ceramic Substrate Market. As automotive manufacturers pivot towards electrification, the need for efficient thermal management solutions becomes paramount. Ceramic substrates are integral in power electronics, which are essential for EVs. The market for electric vehicles is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, thereby propelling the demand for ceramic substrates. This trend indicates a shift in automotive technology, where ceramic substrates play a crucial role in enhancing performance and reliability. Consequently, the Ceramic Substrate Market is likely to experience substantial growth as it aligns with the evolving automotive landscape.

Advancements in Semiconductor Technology

The rapid advancements in semiconductor technology are significantly influencing the Ceramic Substrate Market. As the demand for high-performance electronic devices escalates, the need for reliable substrates that can withstand high temperatures and provide excellent thermal conductivity becomes increasingly critical. Ceramic substrates are favored in the semiconductor sector due to their superior properties, which enhance the performance of integrated circuits. The semiconductor market is expected to reach a valuation of over 500 billion USD by 2026, suggesting a robust growth trajectory. This growth is likely to drive the Ceramic Substrate Market, as manufacturers seek materials that can support the miniaturization and efficiency of electronic components.

Emerging Applications in Aerospace and Defense

The emergence of new applications in the aerospace and defense sectors is a notable driver for the Ceramic Substrate Market. As these industries demand materials that can withstand extreme conditions, ceramic substrates are increasingly being adopted for their thermal and mechanical properties. The aerospace sector is projected to grow significantly, with an expected market size of over 800 billion USD by 2030. This growth indicates a rising need for advanced materials that can enhance the performance and reliability of aerospace components. Consequently, the Ceramic Substrate Market is likely to see increased demand as manufacturers cater to the specific requirements of aerospace and defense applications.