Regulatory Compliance

The Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market is significantly influenced by stringent environmental regulations aimed at reducing emissions and promoting cleaner production processes. Governments worldwide are implementing policies that require refiners to adopt cleaner technologies, which often necessitate the use of advanced catalysts. Compliance with these regulations is essential for maintaining operational licenses and avoiding penalties. As a result, the demand for catalysts that facilitate cleaner refining processes is expected to rise, contributing to the market's growth. This trend underscores the importance of catalysts in achieving sustainability goals within the petroleum refining sector.

Rising Demand for Fuels

The Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market is experiencing a surge in demand for fuels, driven by increasing global energy needs. As economies expand, the need for refined petroleum products rises, leading to a projected market value of 29.1 USD Billion in 2024. This growth is influenced by urbanization and industrialization, particularly in emerging markets. The refining process relies heavily on catalysts to enhance efficiency and yield, making them indispensable in meeting the rising fuel demand. Consequently, the market for catalysts is expected to grow in tandem with the overall fuel consumption trends.

Technological Advancements

Technological innovations in catalyst development are pivotal for the Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market. Advanced catalyst formulations and processes enhance the efficiency of petroleum refining and polymer synthesis, thereby reducing operational costs. Innovations such as nanotechnology and biocatalysts are gaining traction, offering improved performance and sustainability. As these technologies evolve, they are likely to contribute to the market's projected growth to 39.7 USD Billion by 2035. The integration of cutting-edge technologies not only optimizes production but also aligns with environmental regulations, further driving the adoption of catalysts in the industry.

Market Trends and Projections

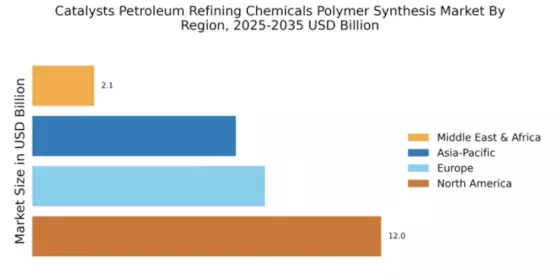

The Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market is projected to experience notable trends that will shape its future. The market is expected to reach 39.7 USD Billion by 2035, reflecting a growing recognition of the importance of catalysts in refining and synthesis processes. The anticipated CAGR of 2.85% from 2025 to 2035 indicates a steady growth trajectory. Factors such as the increasing focus on sustainability, advancements in catalyst technology, and regulatory pressures are likely to drive this growth. These trends suggest a robust future for the catalysts market, emphasizing their critical role in the petroleum refining and polymer synthesis sectors.

Increasing Production of Petrochemicals

The Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market is bolstered by the increasing production of petrochemicals, which are essential for various industries, including plastics and chemicals. The growth in petrochemical production is closely linked to the refining of crude oil, where catalysts play a crucial role in converting hydrocarbons into valuable products. As the global demand for petrochemicals continues to rise, the market for catalysts is expected to expand, reflecting a compound annual growth rate (CAGR) of 2.85% from 2025 to 2035. This growth trajectory indicates a robust future for catalysts in supporting the petrochemical industry's needs.

Market Dynamics and Competitive Landscape

The Global Catalysts in Petroleum Refining Chemicals and Polymer Synthesis Industry Market is characterized by dynamic market conditions and a competitive landscape. Key players are continuously innovating and enhancing their product offerings to maintain market share. This competitive environment drives advancements in catalyst technology, which in turn influences pricing and availability. As companies strive to differentiate their products, the focus on developing high-performance catalysts is likely to intensify. This competitive pressure may lead to increased investments in research and development, further propelling the market's growth as companies seek to meet evolving customer demands.