Regulatory Support

Regulatory support is emerging as a significant driver for the Carbonization Furnace Market. Governments worldwide are implementing stringent regulations aimed at reducing greenhouse gas emissions and promoting waste management solutions. These policies often include incentives for adopting cleaner technologies, such as carbonization furnaces. For example, tax breaks and grants for companies investing in sustainable practices are becoming more common. This regulatory landscape not only encourages the adoption of carbonization technologies but also fosters innovation within the industry. As a result, the Carbonization Furnace Market is likely to experience accelerated growth, with projections indicating a potential market expansion of 20% over the next five years due to favorable government policies.

Rising Energy Demand

The rising demand for energy is a critical driver influencing the Carbonization Furnace Market. As populations grow and economies develop, the need for sustainable energy sources becomes increasingly urgent. Carbonization furnaces offer a viable solution by converting organic materials into biochar and syngas, which can be utilized for energy production. Recent statistics indicate that the global energy demand is expected to increase by 30% by 2030, creating a substantial opportunity for carbonization technologies. This trend suggests that the Carbonization Furnace Market could see a surge in investments and installations, as stakeholders seek to meet energy needs while adhering to environmental standards.

Technological Innovations

Technological innovations play a crucial role in shaping the Carbonization Furnace Market. Advancements in furnace design and operational efficiency have led to improved energy recovery and reduced emissions. For instance, the integration of automation and control systems has enhanced the precision of carbonization processes, resulting in higher quality outputs. Furthermore, the development of hybrid systems that combine carbonization with other waste-to-energy technologies is gaining traction. This evolution is expected to attract investments, as companies seek to modernize their facilities. Market analysis suggests that the adoption of these technologies could potentially increase the market size by 15% within the next decade, reflecting the industry's adaptability to changing environmental regulations.

Sustainability Initiatives

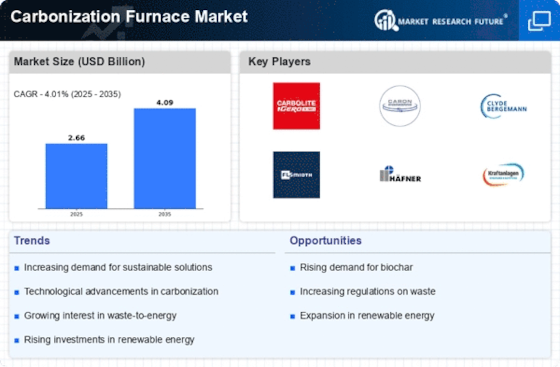

The increasing emphasis on sustainability initiatives is a pivotal driver for the Carbonization Furnace Market. As industries strive to reduce their carbon footprints, the demand for carbonization furnaces, which convert biomass and waste into valuable products, is likely to rise. This process not only generates renewable energy but also minimizes landfill waste. According to recent data, the market for carbonized products is projected to grow significantly, with a compound annual growth rate of approximately 8% over the next five years. This trend indicates a robust shift towards eco-friendly practices, thereby enhancing the relevance of the Carbonization Furnace Market in various sectors, including energy, agriculture, and waste management.

Diverse Industrial Applications

The diverse applications of carbonization technology across various industries serve as a significant driver for the Carbonization Furnace Market. From agriculture to construction, the versatility of carbonized products, such as biochar, is gaining recognition for its benefits in soil enhancement and carbon sequestration. Additionally, industries are increasingly utilizing carbonized materials in the production of activated carbon, which is essential for air and water purification. Market Research Future indicates that the demand for activated carbon is projected to grow at a rate of 10% annually, further bolstering the relevance of the Carbonization Furnace Market. This broad applicability not only enhances market potential but also encourages cross-industry collaborations, fostering innovation and growth.