Expansion of the Automotive Sector

The Broaching Machine Market is significantly influenced by the expansion of the automotive sector, which is witnessing robust growth due to increasing consumer demand for vehicles. As automotive manufacturers strive to enhance performance and reduce production costs, the adoption of broaching machines is becoming more prevalent. These machines are essential for producing key components such as gears, shafts, and other intricate parts that require high precision. The automotive industry is expected to contribute substantially to the Broaching Machine Market, with projections indicating a market value increase of over 20% in the next five years. This growth is likely to be fueled by advancements in electric vehicle technology and the need for lightweight materials, further emphasizing the importance of broaching machines in modern automotive manufacturing.

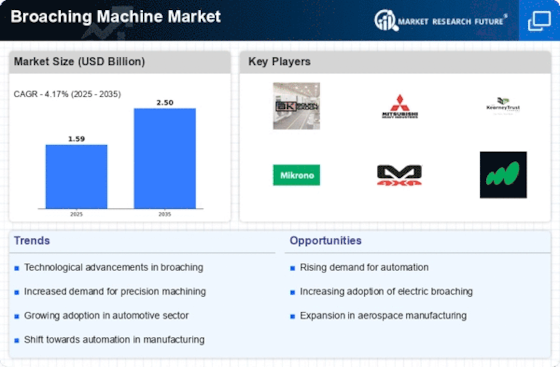

Rising Demand for Precision Engineering

The Broaching Machine Market is experiencing a notable surge in demand for precision engineering components across various sectors, including automotive, aerospace, and manufacturing. As industries increasingly prioritize accuracy and efficiency, broaching machines, known for their ability to produce intricate shapes and high tolerances, are becoming indispensable. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 5.2% over the next few years, driven by the need for high-quality machined parts. This trend indicates a shift towards automation and advanced manufacturing processes, where broaching machines play a crucial role in enhancing productivity and reducing waste. Consequently, manufacturers are investing in innovative broaching technologies to meet the evolving demands of precision engineering, thereby propelling the Broaching Machine Market forward.

Increasing Focus on Manufacturing Efficiency

The Broaching Machine Market is witnessing a growing emphasis on manufacturing efficiency as companies seek to optimize their production processes. This focus is driven by the need to reduce operational costs and improve turnaround times. Broaching machines, known for their ability to perform multiple operations in a single setup, are increasingly favored for their efficiency. The market is expected to see a rise in demand for high-speed broaching machines, which can significantly enhance productivity. Reports suggest that manufacturers adopting these machines can achieve up to 30% reductions in cycle times, thereby improving overall operational efficiency. As industries strive for lean manufacturing practices, the Broaching Machine Market is likely to benefit from this trend, with an anticipated growth rate of around 5.5% in the coming years.

Growing Applications in Aerospace Manufacturing

The Broaching Machine Market is experiencing growth due to the increasing applications of broaching machines in aerospace manufacturing. The aerospace sector demands high precision and reliability in its components, making broaching machines an ideal choice for producing critical parts such as turbine blades and structural components. As the aerospace industry expands, driven by rising air travel and advancements in aircraft technology, the demand for efficient manufacturing solutions is likely to increase. Projections indicate that the aerospace segment could account for a significant share of the Broaching Machine Market, with an expected growth rate of approximately 7% over the next few years. This trend highlights the importance of broaching machines in meeting the stringent quality standards required in aerospace applications.

Technological Innovations in Broaching Machines

Technological innovations are playing a pivotal role in shaping the Broaching Machine Market. The introduction of computer numerical control (CNC) technology has revolutionized broaching processes, allowing for greater precision and efficiency. These advancements enable manufacturers to produce complex geometries with minimal human intervention, thereby reducing the likelihood of errors and enhancing overall productivity. Furthermore, the integration of automation and robotics in broaching operations is expected to streamline production lines, leading to cost savings and improved output. As industries continue to embrace Industry 4.0 principles, the demand for technologically advanced broaching machines is likely to rise, contributing to a projected market growth of approximately 6% annually. This trend underscores the necessity for manufacturers to invest in cutting-edge broaching technologies to remain competitive in the evolving landscape.