Shift Towards Renewable Energy Sources

The Global Boiler Combustion Chamber Market Industry is witnessing a paradigm shift towards renewable energy sources as industries seek sustainable alternatives to fossil fuels. The integration of biomass, biogas, and other renewable fuels in combustion systems is gaining traction, driven by both environmental concerns and economic incentives. This transition not only reduces greenhouse gas emissions but also aligns with global sustainability goals. As a result, manufacturers are developing combustion chambers that can efficiently utilize these alternative fuels, thereby expanding their product offerings and enhancing market competitiveness.

Increasing Demand for Energy Efficiency

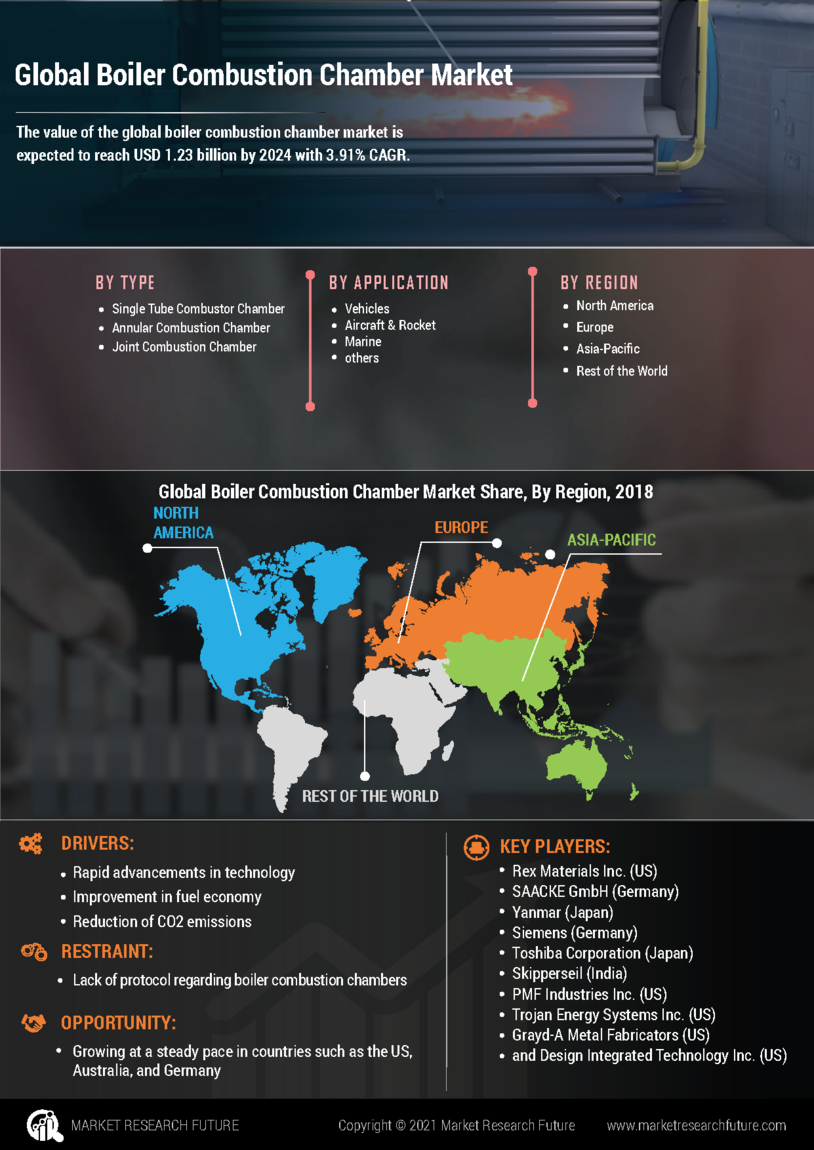

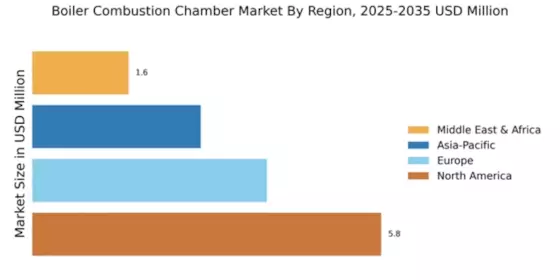

The Global Boiler Combustion Chamber Market Industry experiences a notable uptick in demand for energy-efficient solutions. As industries strive to reduce operational costs and comply with stringent environmental regulations, the adoption of advanced combustion technologies becomes paramount. For instance, the integration of high-efficiency burners and improved heat recovery systems can lead to substantial energy savings. This trend is reflected in the projected market growth, with the industry expected to reach 12.5 USD Billion in 2024 and 20.3 USD Billion by 2035, indicating a compound annual growth rate of 4.51% from 2025 to 2035.

Rising Industrialization and Urbanization

The Global Boiler Combustion Chamber Market Industry is propelled by the rapid industrialization and urbanization trends observed globally. As countries develop, the demand for energy-intensive industries such as manufacturing, power generation, and construction increases. This surge in industrial activities necessitates the installation of efficient boiler systems, including advanced combustion chambers. The growing population in urban areas further amplifies energy consumption, leading to a higher demand for reliable and efficient heating solutions. This trend is expected to sustain the market's growth trajectory in the coming years.

Technological Advancements in Combustion Systems

Technological advancements play a crucial role in shaping the Global Boiler Combustion Chamber Market Industry. Innovations such as smart controls, predictive maintenance, and real-time monitoring systems enhance operational efficiency and reliability. These technologies not only optimize fuel consumption but also minimize downtime, which is essential for industries with continuous production processes. The integration of Internet of Things (IoT) devices in combustion systems allows for better data analytics and performance tracking, thus driving the adoption of modern combustion chambers across various sectors.

Regulatory Compliance and Environmental Standards

The Global Boiler Combustion Chamber Market Industry is significantly influenced by the increasing regulatory compliance requirements aimed at reducing emissions and enhancing air quality. Governments worldwide are implementing stricter regulations concerning NOx and CO2 emissions, compelling industries to upgrade their combustion systems. This regulatory landscape drives the demand for advanced combustion chambers that meet these standards. Consequently, manufacturers are investing in research and development to innovate cleaner technologies, thereby expanding their market share and contributing to the overall growth of the industry.