Growth in Renewable Energy Sector

The renewable energy sector is emerging as a pivotal driver for the blanking machine market. As nations prioritize sustainable energy solutions, the demand for components used in solar panels and wind turbines is escalating. In 2025, the renewable energy market is projected to grow at a rate of approximately 7.4%, creating a substantial opportunity for blanking machine manufacturers. These machines play a crucial role in producing the metal parts required for energy systems, thereby supporting the transition to greener technologies. The increasing investments in renewable energy infrastructure are likely to stimulate demand for high-precision blanking machines, which are essential for ensuring the reliability and efficiency of energy systems. Thus, the blanking machine market is poised to capitalize on this trend, aligning with global sustainability goals.

Increasing Focus on Customization

The growing emphasis on customization in manufacturing is emerging as a key driver for the blanking machine market. As industries seek to meet diverse consumer preferences, the demand for tailored solutions is on the rise. In 2025, the market is projected to grow by approximately 5.8%, reflecting the need for flexible manufacturing processes. Blanking machines that offer customization capabilities enable manufacturers to produce unique components efficiently, thereby enhancing their competitive edge. This trend is particularly evident in sectors such as aerospace and medical devices, where precision and adaptability are paramount. Consequently, the blanking machine market is likely to benefit from this shift towards personalized manufacturing, as companies invest in technologies that facilitate bespoke production.

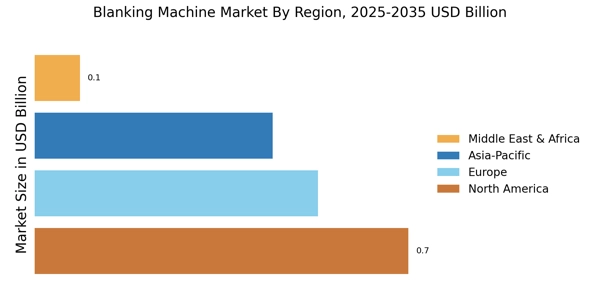

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable surge in demand for blanking machines, driven by the increasing production of vehicles. As manufacturers strive to enhance efficiency and reduce costs, the adoption of advanced blanking machines becomes imperative. In 2025, the automotive industry is projected to account for a substantial share of the blanking machine market, with estimates suggesting a growth rate of approximately 5.2% annually. This trend indicates a robust need for precision-engineered components, which blanking machines are well-equipped to provide. Furthermore, the shift towards electric vehicles necessitates innovative manufacturing processes, further propelling the blanking machine market. As automotive manufacturers seek to optimize their production lines, the demand for high-performance blanking machines is likely to escalate.

Expansion of Electronics Manufacturing

The electronics manufacturing sector is witnessing significant growth, which is likely to bolster the blanking machine market. With the proliferation of consumer electronics and smart devices, manufacturers require precise metal components, which blanking machines can efficiently produce. In 2025, the electronics sector is expected to contribute notably to the overall market, with a projected growth rate of around 6.1%. This expansion is driven by the increasing complexity of electronic devices, necessitating advanced manufacturing techniques. As companies strive to meet consumer demands for innovative products, the reliance on high-quality blanking machines is anticipated to rise. Consequently, the blanking machine market stands to benefit from this upward trajectory in electronics manufacturing, as firms seek to enhance production capabilities and maintain competitive advantages.

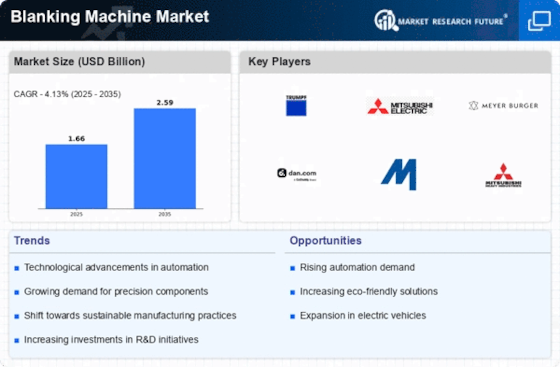

Technological Innovations in Manufacturing

Technological innovations are reshaping the manufacturing landscape, significantly impacting the blanking machine market. The integration of automation and Industry 4.0 principles is enhancing production efficiency and precision. In 2025, the market is expected to witness a shift towards smart manufacturing solutions, with blanking machines incorporating advanced features such as real-time monitoring and predictive maintenance. This evolution is likely to improve operational efficiency and reduce downtime, making blanking machines more attractive to manufacturers. As companies increasingly adopt these technologies, the blanking machine market is expected to experience robust growth. The emphasis on reducing operational costs while maintaining high-quality standards further underscores the importance of technological advancements in driving market dynamics.