Growing Electric Vehicle Market

The Automotive Silicone Elastomers Market is poised for growth due to the expanding electric vehicle (EV) market. As the automotive landscape shifts towards electrification, the demand for silicone elastomers is expected to rise, given their suitability for various EV components. Silicone elastomers are utilized in battery seals, insulation materials, and connectors, which are critical for ensuring the safety and efficiency of electric vehicles. Recent projections indicate that the EV market is set to grow at a compound annual growth rate of over 20% in the coming years, creating substantial opportunities for silicone elastomer manufacturers. This trend highlights the importance of adapting to new automotive technologies and the potential for silicone elastomers to play a vital role in the future of transportation.

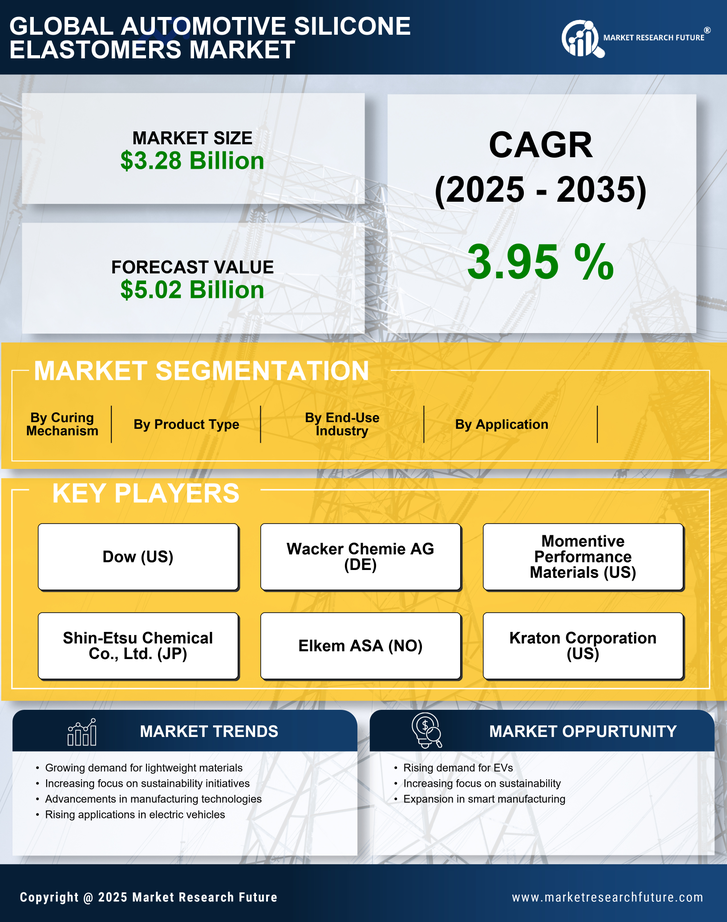

Rising Demand for Lightweight Materials

The Automotive Silicone Elastomers Market is experiencing a notable increase in demand for lightweight materials, driven by the automotive sector's focus on enhancing fuel efficiency and reducing emissions. As manufacturers strive to meet stringent environmental regulations, the adoption of silicone elastomers, known for their lightweight properties, is becoming more prevalent. These materials contribute to weight reduction in vehicles, which can lead to improved fuel economy. According to recent data, the automotive industry is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years, further propelling the demand for innovative materials like silicone elastomers. This trend indicates a shift towards sustainable practices, as automakers seek to balance performance with environmental responsibility.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are increasingly shaping the Automotive Silicone Elastomers Market. As governments implement stricter regulations regarding vehicle emissions and safety, manufacturers are compelled to adopt materials that meet these requirements. Silicone elastomers, with their inherent properties such as flame resistance and low toxicity, are well-positioned to comply with these evolving standards. The automotive industry is witnessing a shift towards materials that not only enhance safety but also contribute to environmental sustainability. Market analysis indicates that adherence to safety regulations is likely to drive the demand for silicone elastomers, as manufacturers seek to ensure compliance while maintaining product integrity. This trend underscores the critical role of regulatory frameworks in influencing material selection within the automotive sector.

Increased Focus on Durability and Performance

Durability and performance are critical factors influencing the Automotive Silicone Elastomers Market. Silicone elastomers are recognized for their superior resistance to extreme temperatures, UV radiation, and chemical exposure, making them ideal for various automotive applications. As vehicles become more sophisticated, the need for materials that can withstand harsh conditions while maintaining performance is paramount. The automotive sector is increasingly incorporating silicone elastomers in components such as seals, gaskets, and insulators, which require long-lasting performance. Market data suggests that the demand for high-performance materials is expected to rise, with silicone elastomers playing a pivotal role in meeting these requirements. This trend underscores the importance of selecting materials that enhance vehicle longevity and reliability.

Technological Innovations in Manufacturing Processes

Technological advancements in manufacturing processes are significantly impacting the Automotive Silicone Elastomers Market. Innovations such as injection molding and 3D printing are enabling manufacturers to produce silicone elastomers with enhanced precision and efficiency. These technologies allow for the creation of complex geometries and customized solutions that meet specific automotive requirements. As the automotive industry embraces automation and smart manufacturing, the demand for advanced silicone elastomer products is likely to increase. Furthermore, the integration of Industry 4.0 principles is expected to streamline production processes, reduce waste, and improve overall product quality. This evolution in manufacturing is anticipated to drive growth in the silicone elastomers market, as companies seek to leverage these advancements for competitive advantage.